Moving from manually built prototypes to an industrial production line, is a huge step especially for a project in an incipient phase, like uRADMonitor. Yet, with strong determination, obstacles melt away, opening the path for the first civilian environmental surveillance network, available to everyone, at anytime, to offer real time data on radiation level trends all around the Globe.

One of the important characteristics is the detectors use the same tubes, checked against a common reference. So the numbers resulting from all the measurements you see on the world map, can be compared to others in the network. The levels measured in CPMs get to have a good meaning, but also the absorbed dose approximation, that can be compared to indications of other units commercially available. But more on this later.

To keep up with the current high demand of uRADMonitor units, but also to move to professionally built devices, the manufacturing has been outsourced to China and split into three: the aluminium enclosure, the rubber gaskets to seal the container to make it rainproof (for uRADMonitor units mounted outside) and the most important, the PCB circuit board with the Geiger tube, the microcontroller and all the tiny electronics.

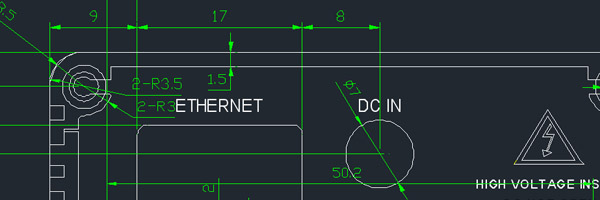

First thing to do was to finalise the designs. The enclosure, the PCB and all the other components were drawn using design software and prepared for the manufacturer. Then some changes were required and a few revisions were made. Finally the production got the green light, and the first components were getting out of the factories.

The design for the Aluminium case is black with a white logo and a few text indications for the two connectors. After a long road from the drawing board to the production, the cases are finally ready. Combined with the rubber gaskets, we have a perfect rainproof solution for deploying the uRADMonitor units outdoors:

codemore code

~~~~