Developed to meet the growing demand for accurate, localised data, the MODEL A4 is as a modular, durable, and easy-to-maintain device, launched in late 2023 to improve reliability and simplify field servicing in diverse outdoor conditions.

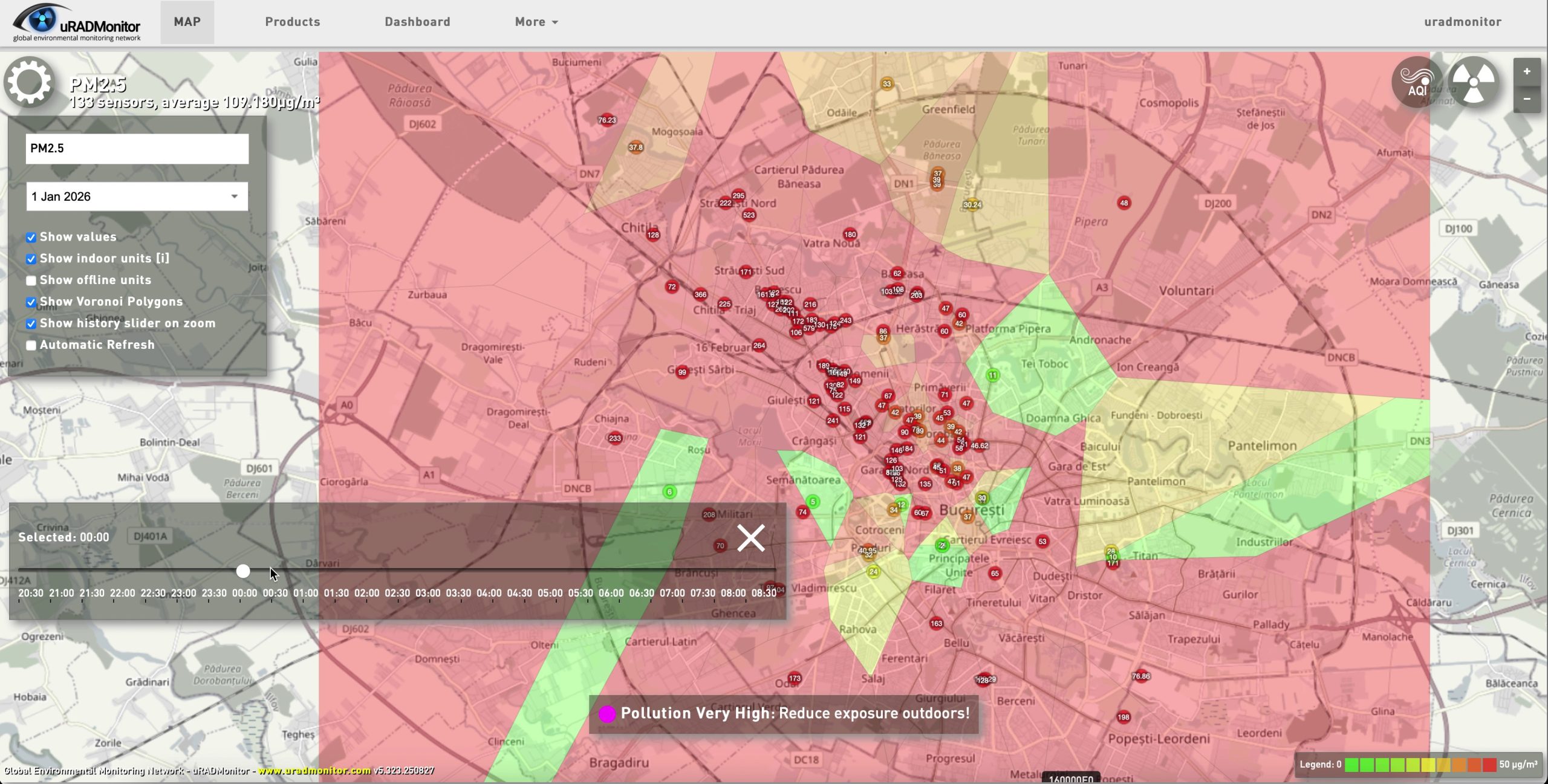

Its multi-parameter sensing capabilities, combined with the weatherproof enclosure and the versatile modular design that simplifies field installation and maintenance, have enabled rapid adoption by both individual users and large-scale projects like the air quality monitoring network deployed in Bucharest.

Already at its 3rd hardware iteration, some notable improvements were added, so let’s see some of those here.

Field deployment feedback demanded more ruggedness

In Bucharest, Tonka took care of deploying more than 100 uRADMonitor® MODEL A4 sensors. They successfully accomplished a sensitive and complicated job, as shown here . During the following months they were able to give us valuable feedback on the problems they faced and what needed to be improved. For example, the initial resin enclosures, while visually appealing thanks to the high-resolution printing process, proved too brittle to withstand the stress from the stainless steel connectors used for pole mounting. Several units cracked, allowing rainwater to seep in and damage the sensitive internal electronics. Total loss, obviously.

We switched to FDM printing, which allowed us to use ASA, a durable, UV-resistant plastic ideal for outdoor use and significantly stronger than standard ABS. While ASA provides excellent strength on the X and Y axes, the Z axis , composed of stacked layers, is more vulnerable to separation under impact. In typical conditions this wouldn’t be an issue, but with many sensors installed in parks, occasional hits from children’s play introduced unexpected stress.

To ensure long-term reliability, additional reinforcement was added to protect the Z axis:

The enclosure design was changed again, this time to add 3 metallic threaded rods. They not only secure the Z axis completely, squeezing all layers together, but they also go around the mounting brackets. So when the collars are closed on the poles, they push against the metal, not the plastic and the brackets won’t break. Here’s a picture with the result, left the regular enclosure , right the new one with steel rods:

The AIRLAB 2025 Microsensors Challenge

AIRLAB 2025, organized by AIRPARIF France, is a large-scale air quality sensor testing campaign where various devices are evaluated under real-world conditions; this not only helps developers improve their products through objective feedback, but also acts as a competitive benchmark, highlighting the most accurate and reliable sensors to guide future customers in making informed choices. In their own words, this is about “AN INNOVATION ACCELERATOR DEDICATED TO AIR QUALITY”.

uRADMonitor® participated in both the 2021 and 2023 editions of AIRLAB, and we’re deeply grateful for the exposure and valuable feedback received from AIRPARIF and its partners. The experience had a significant impact on our work, directly contributing to the improvement of our technology. That’s why we’re fully committed to making a strong showing at this year’s edition.

The “MODEL A4” was accepted as a candidate for the 2025 AIRLAB edition. For this competition, a custom variant was developed featuring an upgraded NO2 sensing system – replacing the previous MOX sensor with a more accurate electrochemical sensor. This change increases sensitivity and reduces unwanted cross-sensitivity to other gases, helping to avoid false readings. Integrating multiple sensors in a compact design is always challenging, but we’re pleased to have achieved this improvement, especially given the importance of monitoring NO2 levels.

The first step was designing a new sensor board to accommodate the upgraded digital NO2 sensor, which also required dedicated firmware to handle its specific communication protocol. Unlike analog variants, this digital electrochemical sensor comes pre-calibrated, with compensation factors stored in its internal memory based on factory lab testing. We’re especially grateful to our partners at Winsen, who provided exceptional support and delivered this custom solution in record time, making this MODEL A4 upgrade possible.

Winsen Electronics Technology Co. Ltd. was founded in 2003 (having roots as far as 1990s), is a leading high-tech enterprise specialising in the R&D, production, and sales of sensing products, particularly gas sensors. Listed on the Growth Enterprise Market since 2009, the company holds over 100 patents and adheres to multiple international certifications, positioning itself among the top global sensor manufacturers. It’s no surprise they were able to deliver such outstanding support tailored to our needs in such a short timeframe.

The show must go on

The new sensor is bigger both above and under the PCB layer and would not fit the enclosure. Redesigning it to fit would imply changing both the plastic and the aluminium lid. Instead of doing that, we kept the lid and designed a small plastic part that covers the extra space after the two PCBs are inserted. This is fixed in small plastic brackets and can be removed when access to the internals is required.

Continuous product improvement is a natural part of any technological lifecycle, driven by real-world feedback and evolving user needs. At uRADMonitor, we remain committed to innovation, building on lessons learned to deliver more robust, accurate, and serviceable air quality monitoring solutions. With the MODEL A4 undergoing its first round of independent testing in the AIRLAB 2025 challenge, we look forward to the results and to further refining our technology based on this valuable benchmarking opportunity.

codemore code

~~~~