uRADMonitor® MODEL A4 was built on community feedback that repeatedly indicated the importance of a modular design. The board with sensors should be separated and so can be changed easily. Besides that , things like a better microcontroller that will allow OTA updates, a stronger WIFI connectivity and a very nice Stevenson shield were also put on the list. So with all these in mind, we went for a new product to meet all the requirements.

Designing and building the A4 was fun and somewhat quick, as we took advantage of our huge 10 years experience with IOT sensors and all the community feedback we received so far. This article is a production log to show the important step in bringing an IOT hardware sensor to life. Feel free to read it with a curious eye and be inspired with what we achieved. Then last but not least, feel free to get back to us to provide feedback and ideas using the comments section below.

Get ready for a long production log, on some of the steps we took to bring this product to life.

The concept and general directions

Following the semiconductor crisis of 2022, we had to reevaluate our supply chains . The crisis hit us hard as critical components used in our products were missing on the market . The few existing stocks offered high prices and were not very promising on the long run. Turning a disadvantage to an advantage, we decided to use the moment to upgrade the hardware to allow more advantage options like OTA upgrade, better security and more features , like fancy RGB LEDs, nicer internal web interface. All this while bringing costs down. It was obvious the main microcontroller needs to be upgraded based on cost and availability. We opted for the ESP8266, but instead of going for discrete components with a long BOM, we simply opted for the Arduino compatible Wemos D1, planing to release the entire design as opensource on Github.

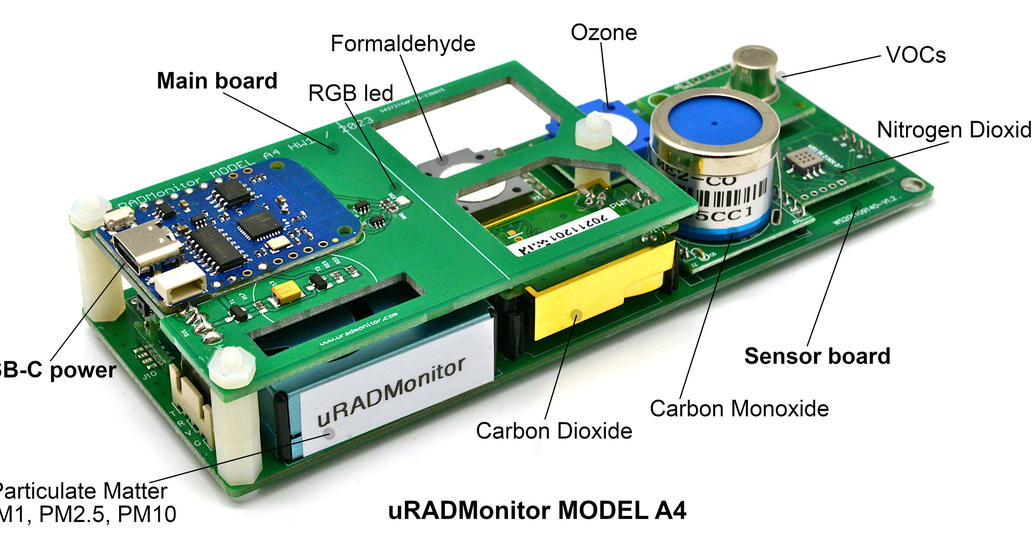

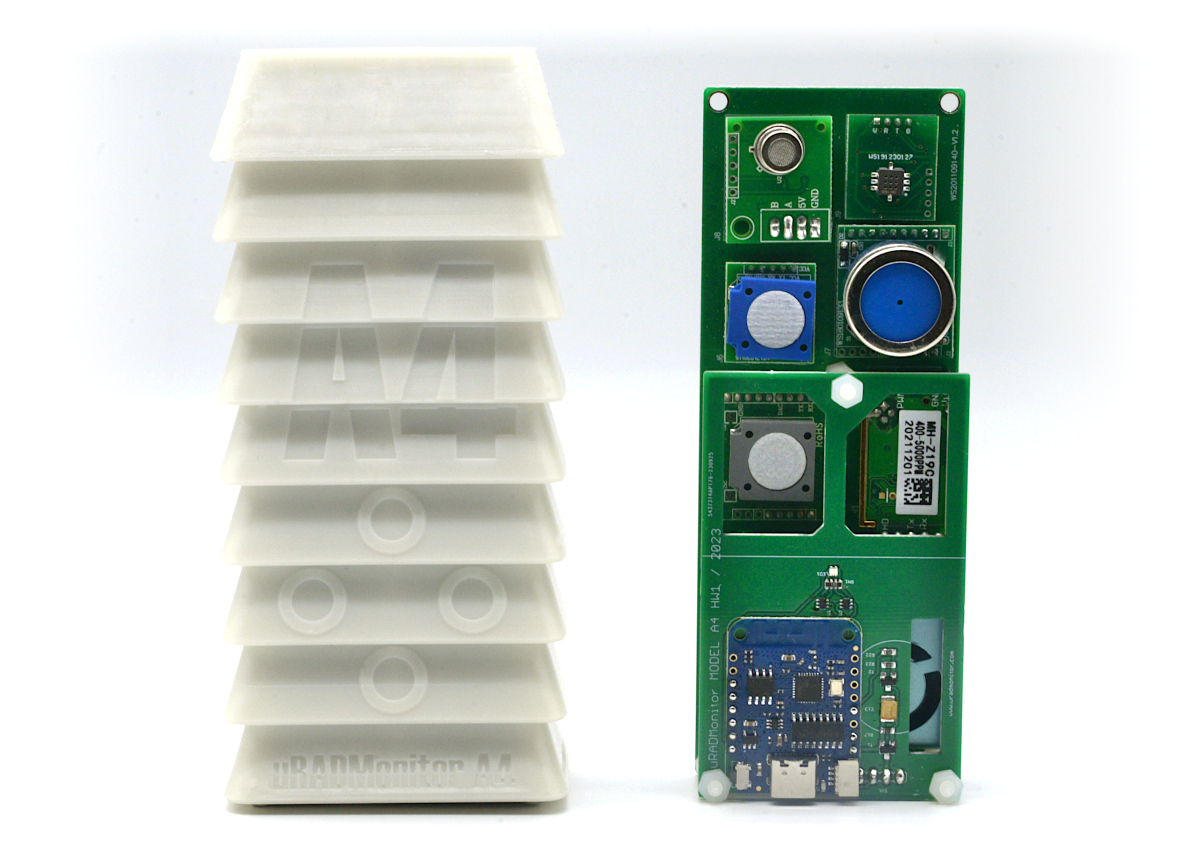

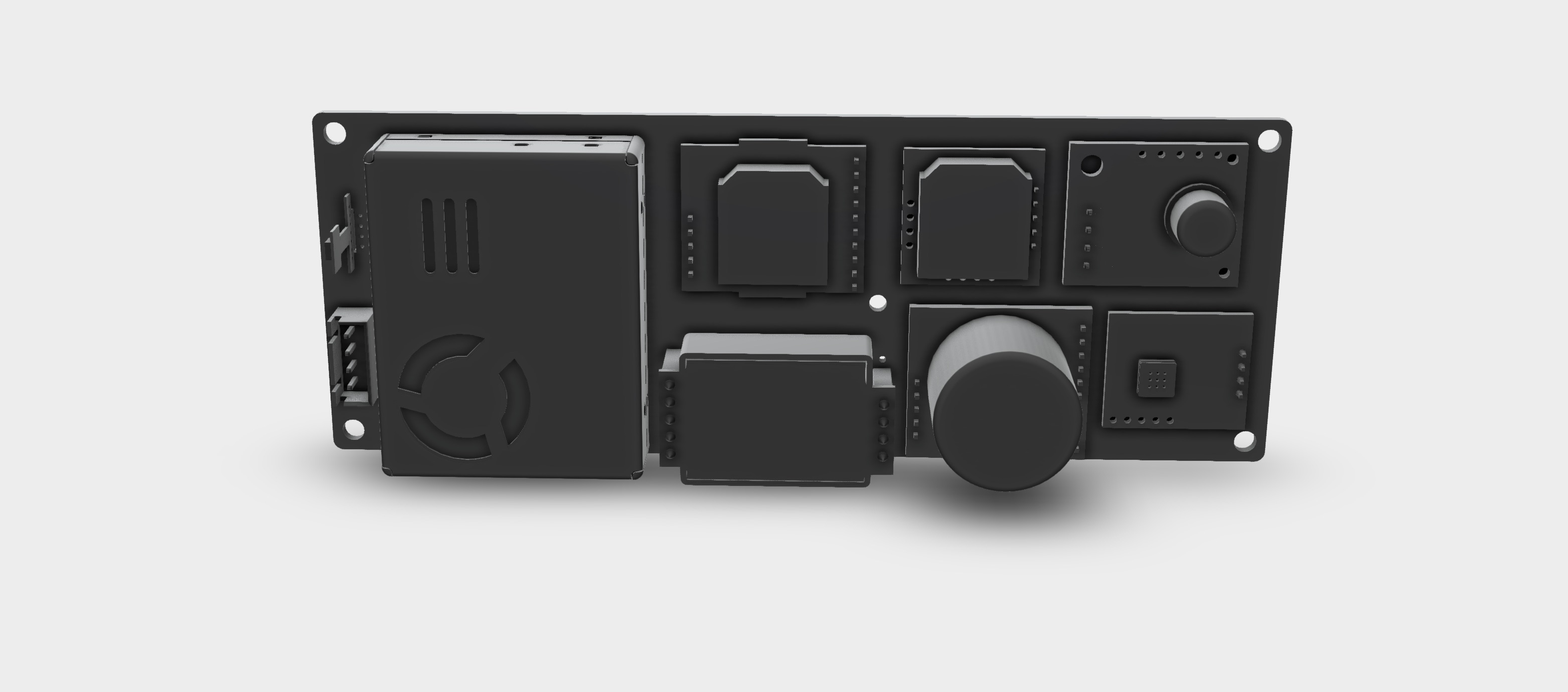

The most important feature about this product is the modular design, so we went for a separate sensor board that will be connected to the main IOT board via a connector, making replacements easy even in the field. Many of our sensors are installed on poles, on high buildings and maintenance was a constant issue due to the man hours needed to take a malfunctioning sensor back to our lab and re-installing the fixed unit or a replacement back on the field. With the A4, everything can be fixed on the spot, an operator will simply replace a part and the unit will be back online in seconds.

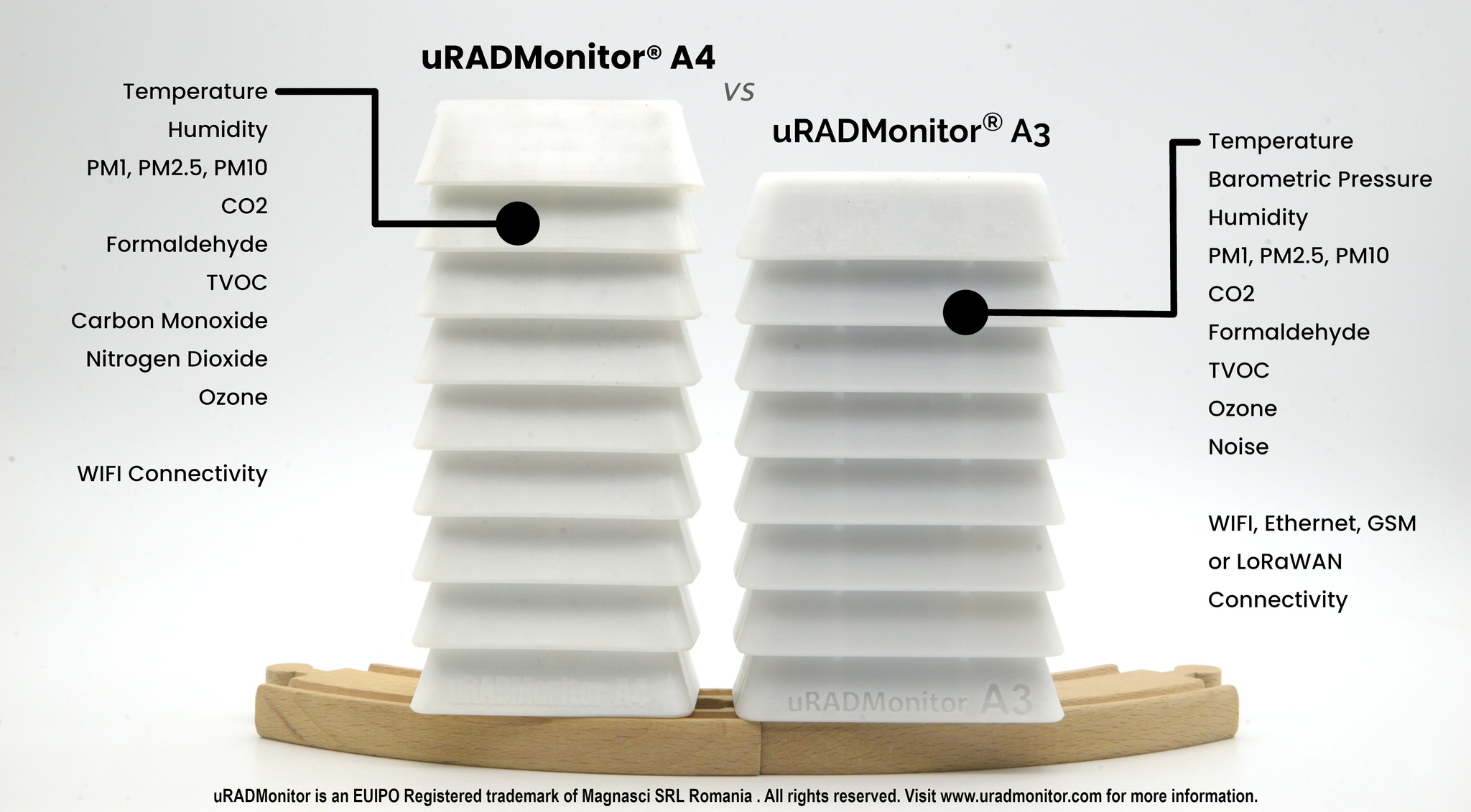

The sensor board is very similar to what we use on the uRADMonitor MODEL A3. Several high quality, calibrated digital sensors are connected to a serial UART multiplexer. This means that the entire sensor board behaves like a single sensor, with an automated switch cycling to each of the individual sensors one at a time. This makes the interface to the main motherboard a 4 wire solution and simplifies many aspects of this design. When something goes wrong or when the lifetime of a sensor is up, the sensor board can be replaced with a new one on the field.

The configuration of the selected sensors continues the multiparameter capabilities introduced by the MODEL A3, measuring a wide list of chemical and physical factors including: air temperature, humidity, particulate matter PM1, PM2.5, PM10, Ozone (O3) , Formaldehyde (CH2O), Carbon Monoxide (CO), Carbon Dioxide (CO2), Nitrogen Dioxide (NO2), Volatile organic compounds (VOCs).

Sept 1, 2023 – The Preamble

In our field, we have to be innovative and constantly expand our technology. Innovate or step aside. Thus, meet the uRADMonitor® MODEL A4, our newest multi-parameter #airquality now available on our online shop. But how did we get here? Read on.

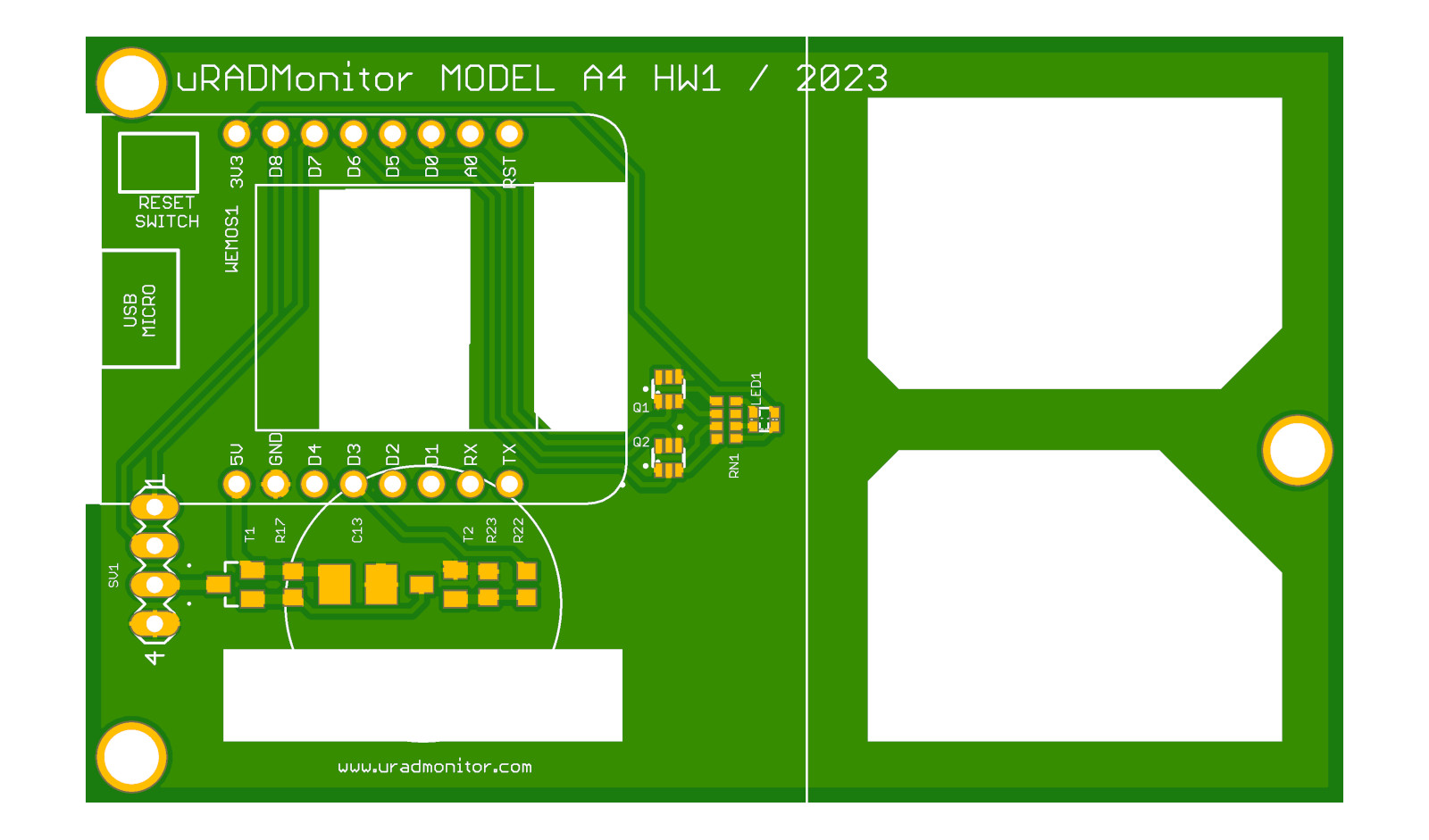

Sept 09, 2023 – Producing the PCB

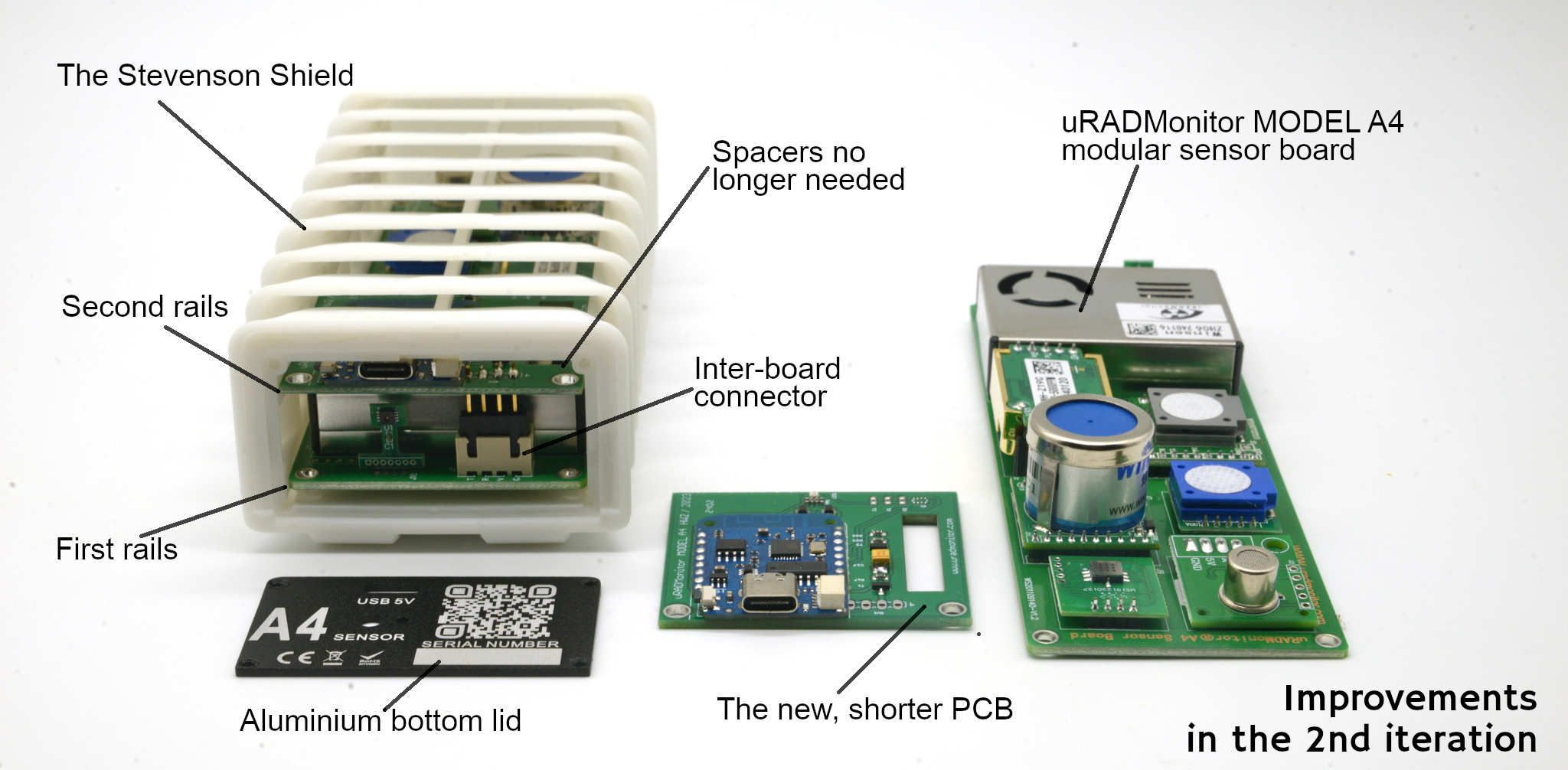

The first PCB, was longer, and would fix to the sensor board via 3 spacers. Those could be either plastic or metal. The entire assembly would then slide in the enclosure on two side rails. Everything was designed to be simple and to allow easy further maintenance.

Nov 26, 2023

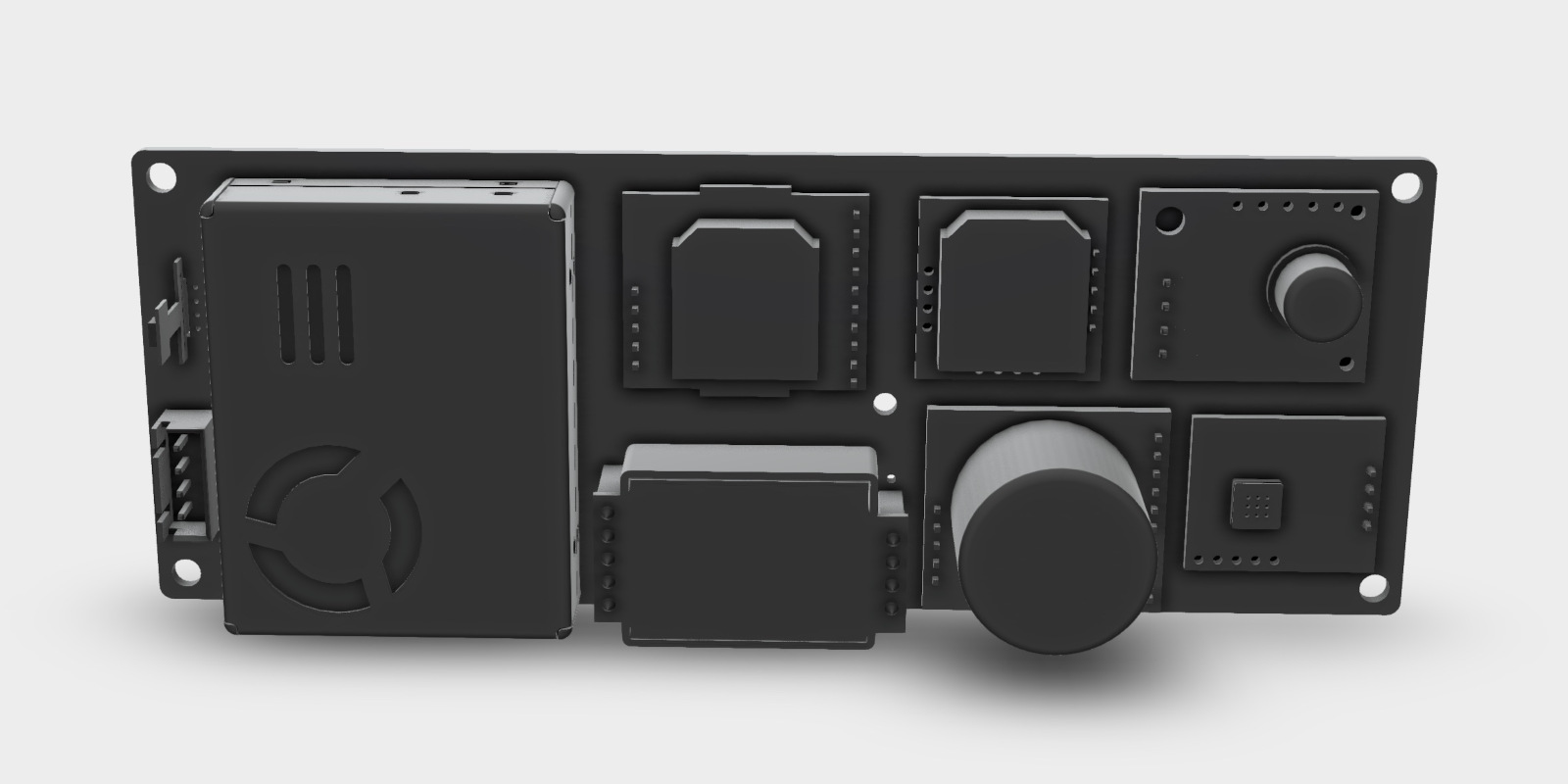

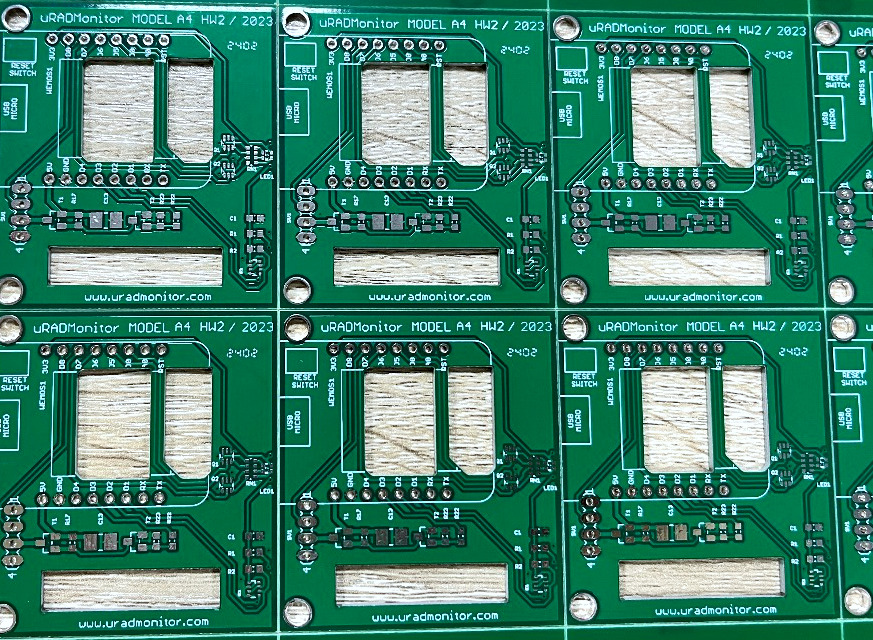

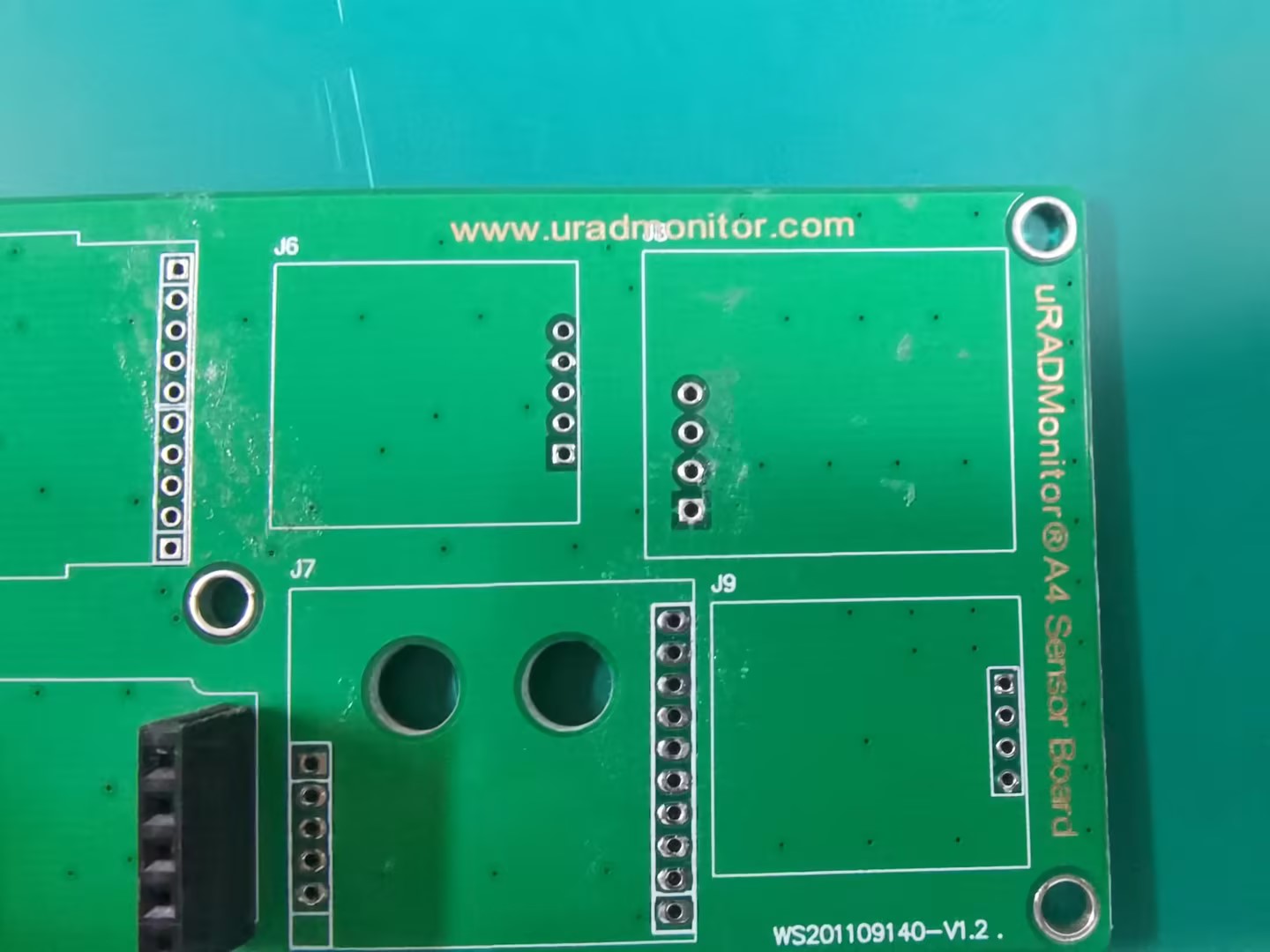

![]() Meet our new uRADMonitor MODEL A4, a multi-parameter #airquality sensor that employs cutting-edge technology to deliver real-time, accurate data on toxic gases and particulate matter, full specs here. . We finally have the first production PCBs ready. From the rendering above, see the actual thing below.

Meet our new uRADMonitor MODEL A4, a multi-parameter #airquality sensor that employs cutting-edge technology to deliver real-time, accurate data on toxic gases and particulate matter, full specs here. . We finally have the first production PCBs ready. From the rendering above, see the actual thing below.

We launched a campaign to popularize the new sensor. “![]() Equip yourself with the knowledge to optimise your air quality and create a healthier environment effortlessly. Breathe confidently, live healthily while contributing to the network expansion.”

Equip yourself with the knowledge to optimise your air quality and create a healthier environment effortlessly. Breathe confidently, live healthily while contributing to the network expansion.”

![]() The MODEL A4 can be integrated with home automation systems and thanks to its robust enclosure, can also be used outdoors, right out of the box!

The MODEL A4 can be integrated with home automation systems and thanks to its robust enclosure, can also be used outdoors, right out of the box!

Nov 30, 2023

A limited production lot is ready to ship, just in time for Black Friday for a few lucky users. This is how the assembled unit looks:

Dec 1, 2023

Our sensors lit in blue, yellow and red on a very special ocassion today: Romania’s national day. “La mulți ani România! La mulți ani români!”

uRADMonitor was conceived in Romania almost 10 years ago. In a way, it carries a piece of the Romanian spirit. Today, on Romania’s national day, we take a moment to congratulate Romania and the Romanian people!

Regardless of where you live, you’ll have to admit those coloured LEDs are pretty.

Dec 11, 2023

The new URADMonitor A4 uses a RGB LED to indicate pollution levels in real time. It also contains 8 sensing elements to measure 11 #airquality parameters! We find the visual indication a very important feature of this design. It delivers quick and effective notifications on what the sensors detects. And it does it in real time!

Jan 2, 2024

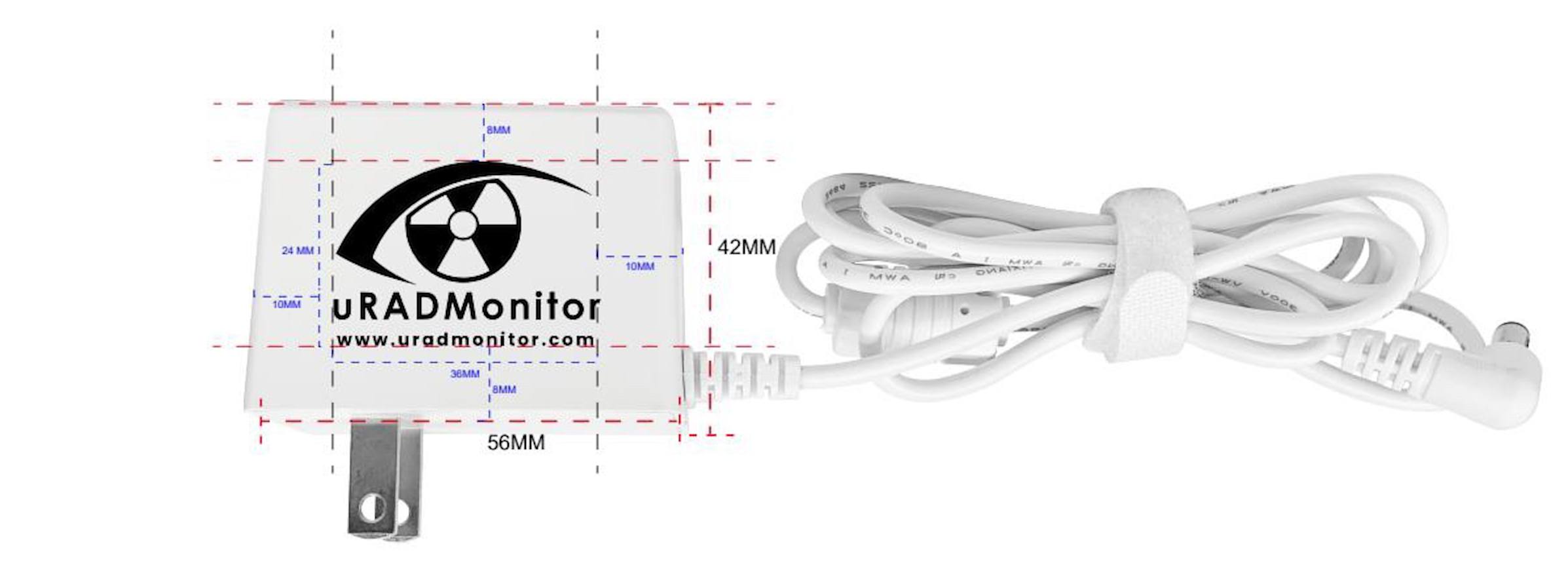

Starting with mid-January, all uRADMonitor sensors will ship with custom made, certified power adapters.

Jan 5, 2024

As a backup, we contracted 2 more factories to produce a total of 3 different adapters for multiple uRADMonitor products. Here’s the second design:

Jan 6, 2024

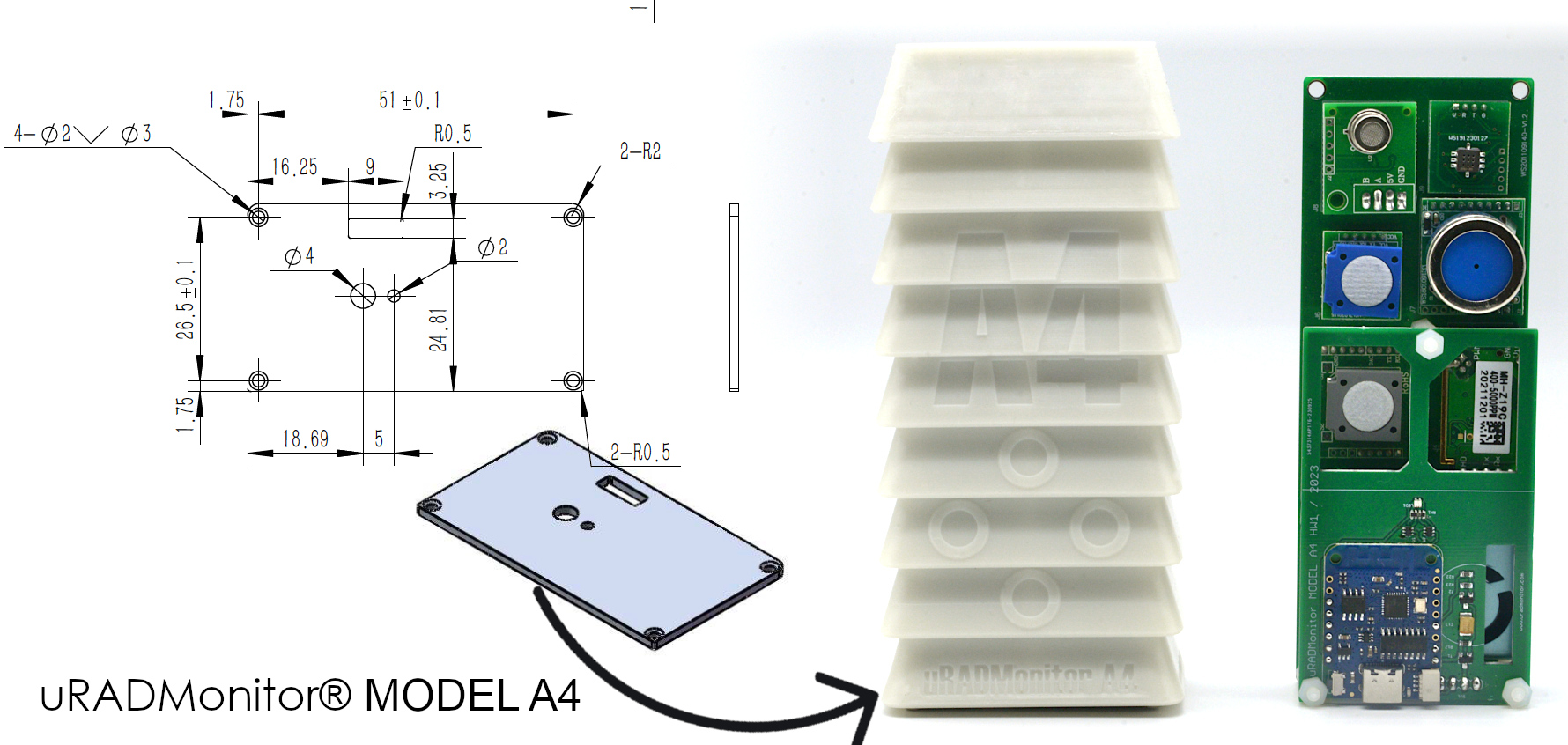

The first A4 units has plastic bottom lids, that close the enclosure with screws. We now made new metallic bottom lids for the uRADMonitor A4 enclosure:

Jan 10, 2024 – The second iteration

Designed in late December, the second iteration of the MODEL A4 will soon be ready. Below is a picture with the first panellised PCBs. This development went in paralel with the aluminium lid design and the modifications required to the enclosure.

The idea with this new design is that we can drop the 3 fixing screws / spacers and so the board can be smaller (and cheaper). The microcontroller PCB pictured above, will connect to the sensor board via the same connector, but now there is a second pair of rails in the enclosure to hold this PCB at the right distance above the sensor board. We no longer need the 3 spacers and this lowers BOM list but more important, saves time when assembling!

Of course, the enclosure also had to be modified to add the second pair of rails. These rails are shorter, matching the PCB length, so the board will stop at the right distance, for the USB-C connector to be perfectly aligned to the aluminium lid.

Jan 15, 2024

Half of January is here, and the new power adapters are ready. What a trilling satisfaction to draw the concept and then a few days later to hold the actual thing! Here at uRADMonitor we’re passionate about developing innovative technology. We love what we do and we try to constantly improve. In the end, our goal is to build something that matters, that has an impact on the lives of many! Technology is our best friend.

Jan 15, 2024

We all love powerful lasers . Especially those that engrave the new MODEL A4 bottom lids. Here’s how they came out.

Jan 15, 2024

More than 100 uRADMonitor A4 sensors are to be deployed in Bucharest for complex #airquality monitoring. The new sensor offers a modular design, where the sensing board can be easily replaced, improving maintenance. Here is one of the first PCBs. Complete specs on the model A4 page.

Like with the adapters above, it all started with the design. Now the actual thing is ready.

Jan 15, 2024

uRADMonitor model A4: Creating the PCBAs, that means putting all the tiny electronic components on the panellised PCB and soldering them in place. This is done on a special machine called a pick and place.

Jan 17, 2024

Here’s what that pick and place machine worked so hard to produce. Meet the 2nd iteration of the “model A4” #productionlog

Jan 18, 2024

uRADMonitor Model A4 #productionlog #8: The Firmware is written and the RGB LED rainbow confirms boot-up sequence is successful. This procedure is now done on 200 such devices before the 2nd board with the sensors is connected. #uradmonitor

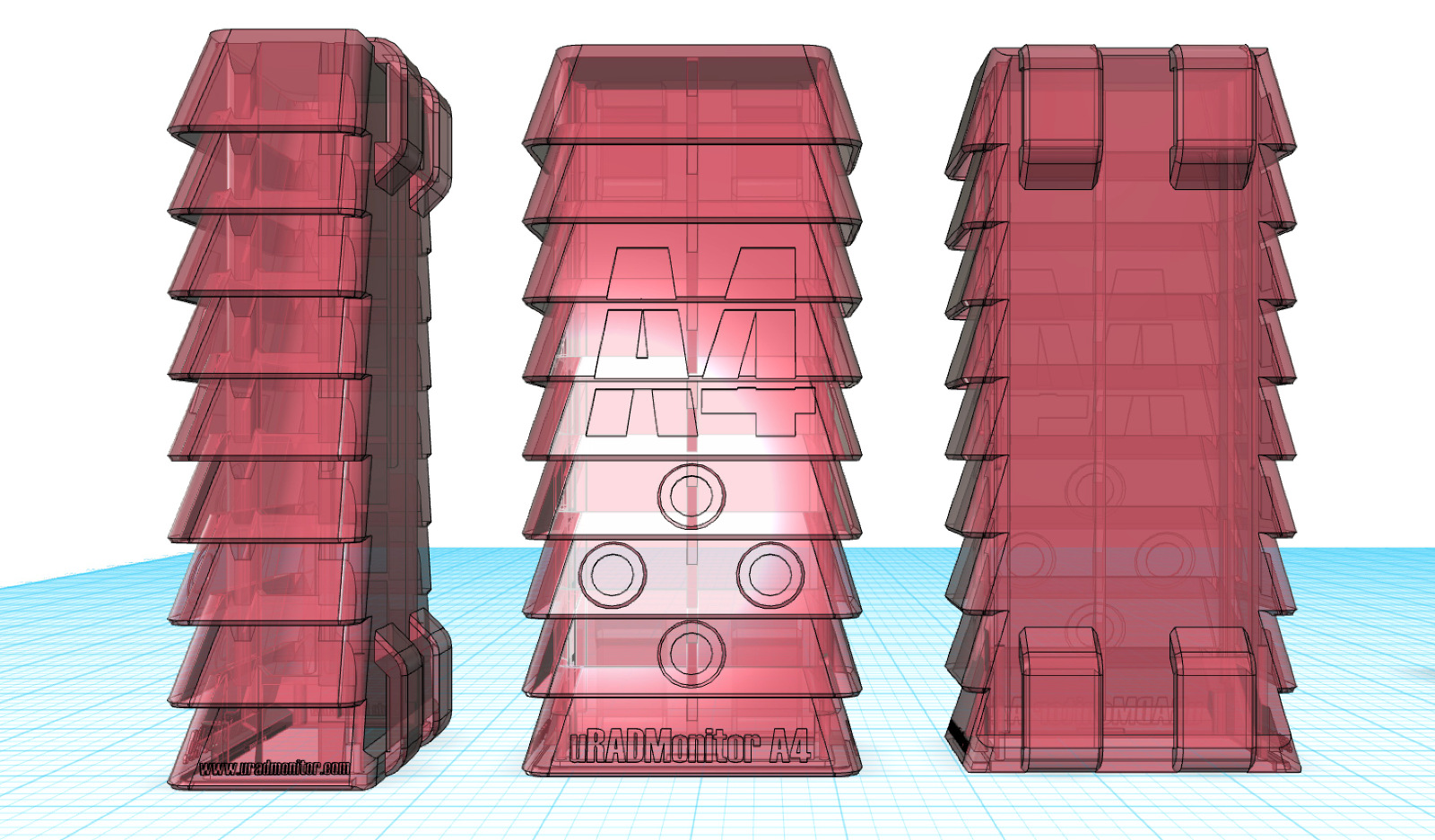

Feb 2, 2024 – The Stevenson shield enclosure

One great thing about the A4 is that tries to answer to all previous issues with our other sensors. For instance, installing a sensor outdoors can be problematic for two reasons: 1. You want it protected from rain -but- 2. you cannot close the box as it needs direct, well ventilated access to the air around, to measure it. While previous projects answered this in a way or another, the model A4 comes with the best approach .

It has its own outdoor-ready Stevenson shield, a special type of enclosure that reflects Sun’s radiation and protects the sensitive electronics from Rain and Snow, all these while being completely open to the air around. And needs no special ventilation as it uses plain simple air convection.

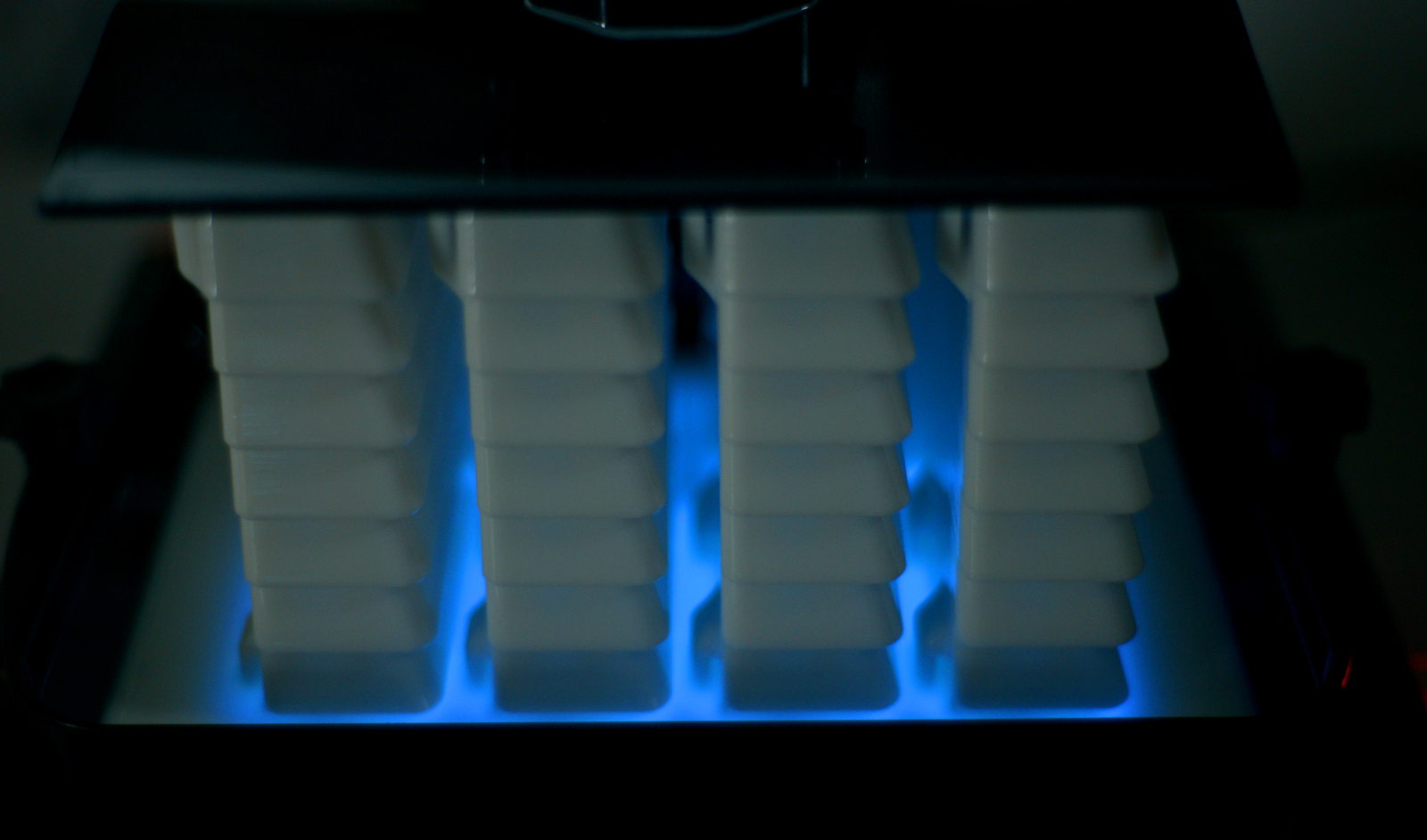

Our printers worked hard to produce a huge amount of enclosures. We used a special white low odour resin that works best at outdoors and is comparable in strength to hard plastics like ABS or ASA. But again, it’s an awesome feeling to move from the digital design to the actual thing. The enclosures came out great!

The RGB LED inside diffuses through the plastic, a visual effect that we tried to boost using those circular patterns on the front.

Feb 11, 2024 – The first production batch

The story doesn’t end here. Like with all our products, there will be constant work to improve the sensors. Model A4 is no exception, there are so many things to come: OTA firmware updates, real time notifications, improvements to the electronics . As these happen, we will continue to remake the A4 and iterate it to perfection.

For now the current hardware performs wonderful. We’ve completed a huge work to produce and assemble more than 100 sensors for a major deployment in Bucharest.

One particular thing we wanted to have was the powersaving function. These sensors will not work constantly, they have a preconfigured duty-cycle to preserve their lifespan, especially the fan. We plan to see them up and running in Bucharest for many years from now on.

codemore code

~~~~