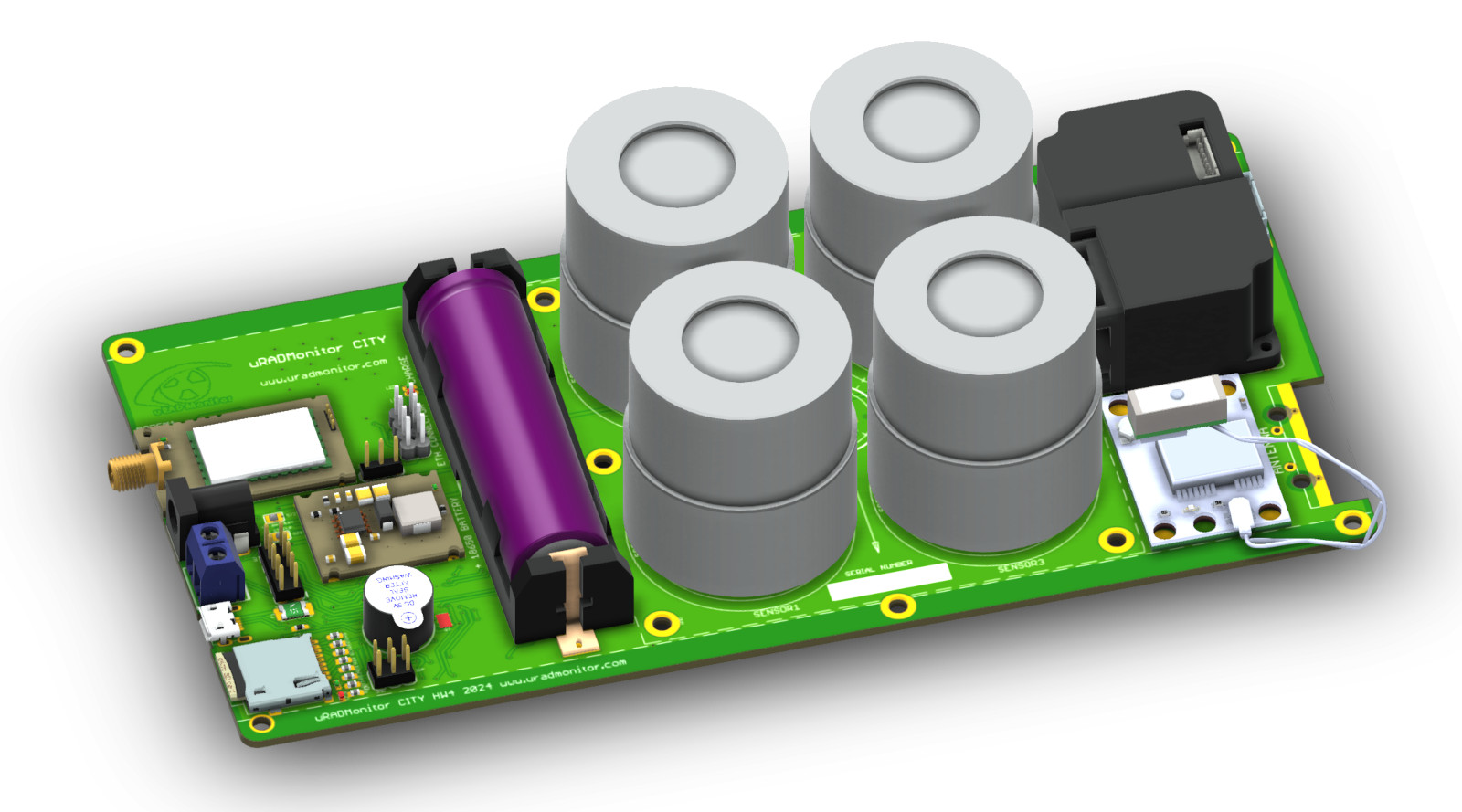

The MODEL CITY is our professional range sensor featuring 4 large volume electrochemical gas sensors that track gases down to trace levels of 1PPB. All this with an excellent accuracy thanks to the innovative electronic design that minimises noise levels at low concentrations. The new design measures Ozone, Nitrogen Dioxide, Sulphur Dioxide, Carbon Monoxide , Particulate Matter (PM1 / PM2.5 / PM10) and Temperature, Barometric pressure and Humidity.

1. The new motherboard

The current motherboard is a complete rework of the previous . We dropped everything and started from scratch, in order to make room for all the new ideas.

The new motherboard offers new features for this complex sensor:

- Ethernet connectivity is now added to the already rich list of options: LoRaWAN, WIFI or GSM.

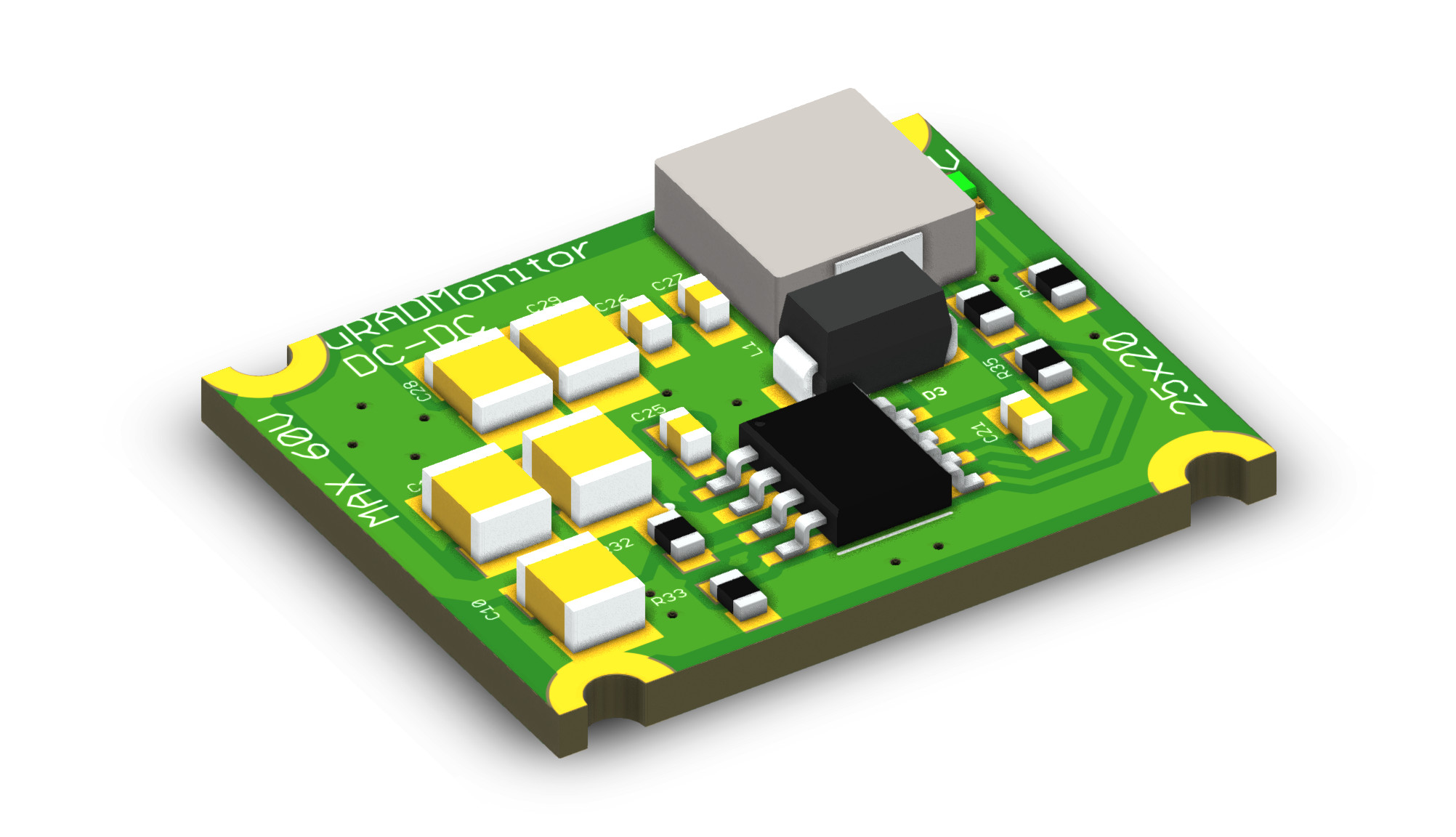

- A modular power supply that makes repairs easier but also allows us to customise the units for broader uses. For instance now we have 3 power supplies designed for the model CITY, that can work with different input voltages. While the default allows powering the CITY with anything between 6 to 60V, there are two more based on a different semiconductor that can take 6 to 24V, respectively 6 to 100V input voltage.

- With Ethernet support and a power supply that can take up to 60V (or 100V with the custom power supply), using POE becomes possible.

- Built in GPS support, with a built in Antenna . Now, all CITY units will have their location determined automatically

- The new motherboards can hold a rechargeable high capacity 18650 Li-Ion battery and there is a power management system in place with P-CH switches that can run the board in a power efficient manner, including intervals of hibernation with complete power shutdown. The battery levels are constantly monitored by the microcontroller, to serve power management logic. Having a battery operating capability, Radio connectivity and built in GPS opens the way for mobile use! CITY units can be installed on moving platforms and will measure air quality mapped to location! (*)

- An slot for a micro SDCARD to backup all data locally. The card is a high-capacity, gigabyte range card that can hold all measurements for months . These can be downloaded at any time. The SDCARD (*)

- Extension port . More sensors can be added to the CITY and aggregates with the unit’s data. The extension port also includes general I/O pins, that can be used to control LEDs, Relays , Fans, and more.

(*) The battery and the sdcard are optional and are not equipped in the default CITY unit configuration.

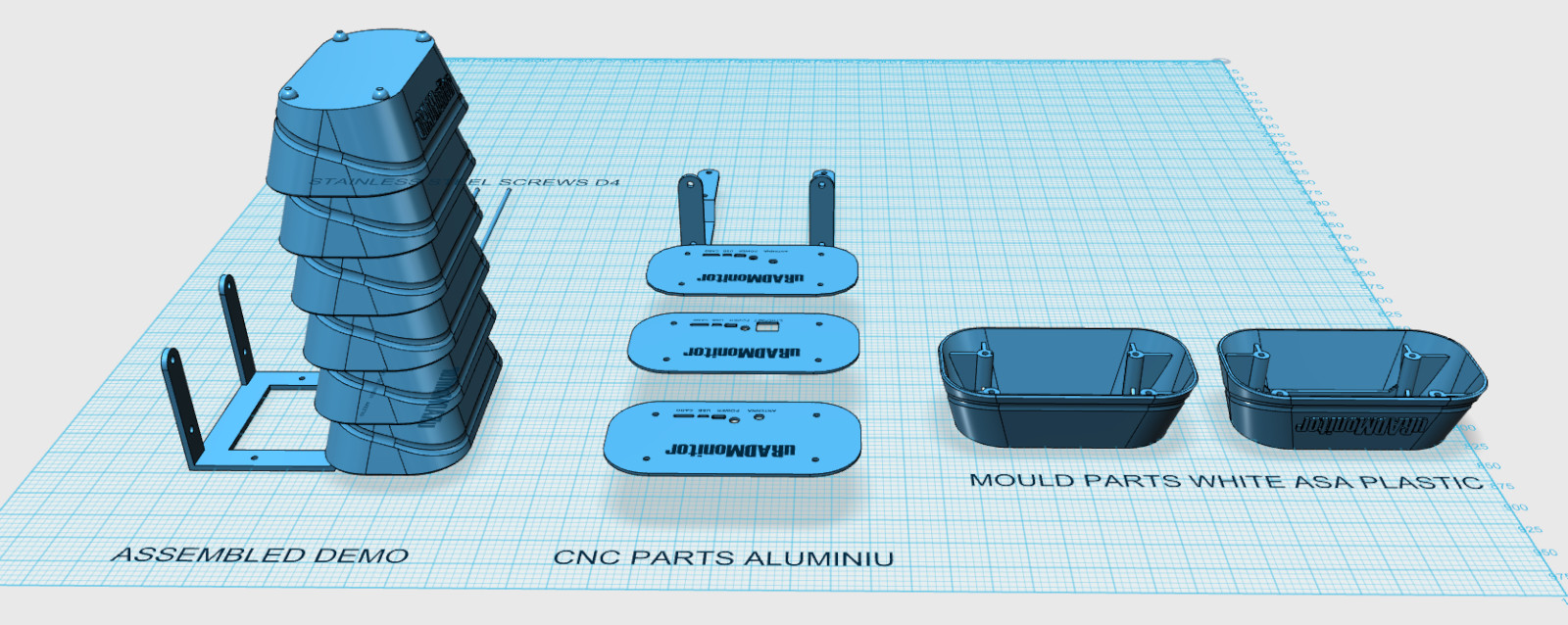

2. The new enclosure

Because of it’s big size and weight , previous versions had complicated solutions for the unit enclosure . It had to work outdoors, offer proper ventilation and protection to internals.

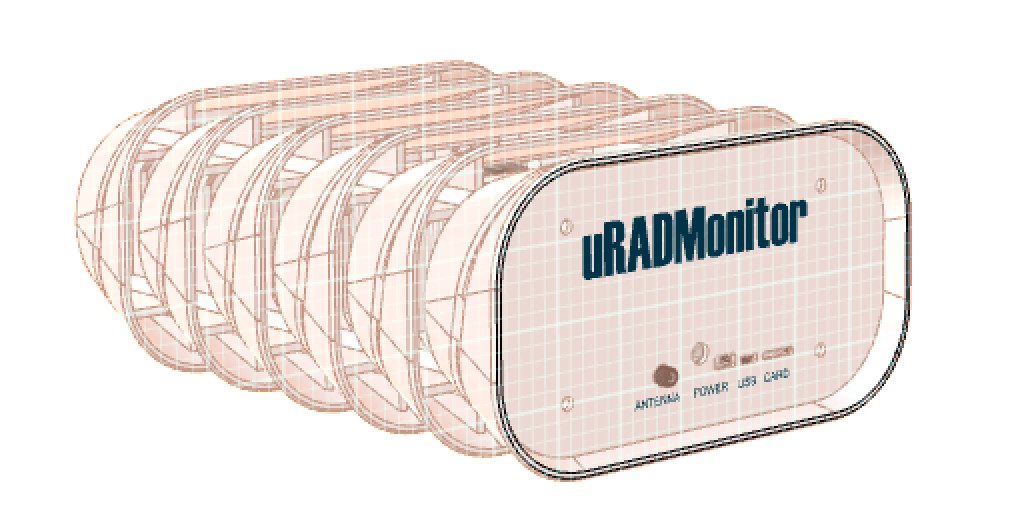

We finally designed a proper, huge enclosure for the CITY unit. We opted for a high quality Stevenson type of enclosure (Stevenson shield) , made of durable, UV resistant ASA plastic.

This solution is very similar to what we use in the model A4, but the size is a few times bigger. We had to use harder plastics and thicker walls. The 6 Stevenson elements are made of ASA plastic and they are fixed together using 4 long threaded rods. There are two options to put this to production: plastic injection mould, and 3D printing. Normally you go for a mould when you are 100% there will be not future changes, at least in a short term. We already did a few changes to the plastic parts so it was obvious there are still things to improve and we cannot commit (yet) to a mould, that once you make it you need to use it to amortise the initial costs.

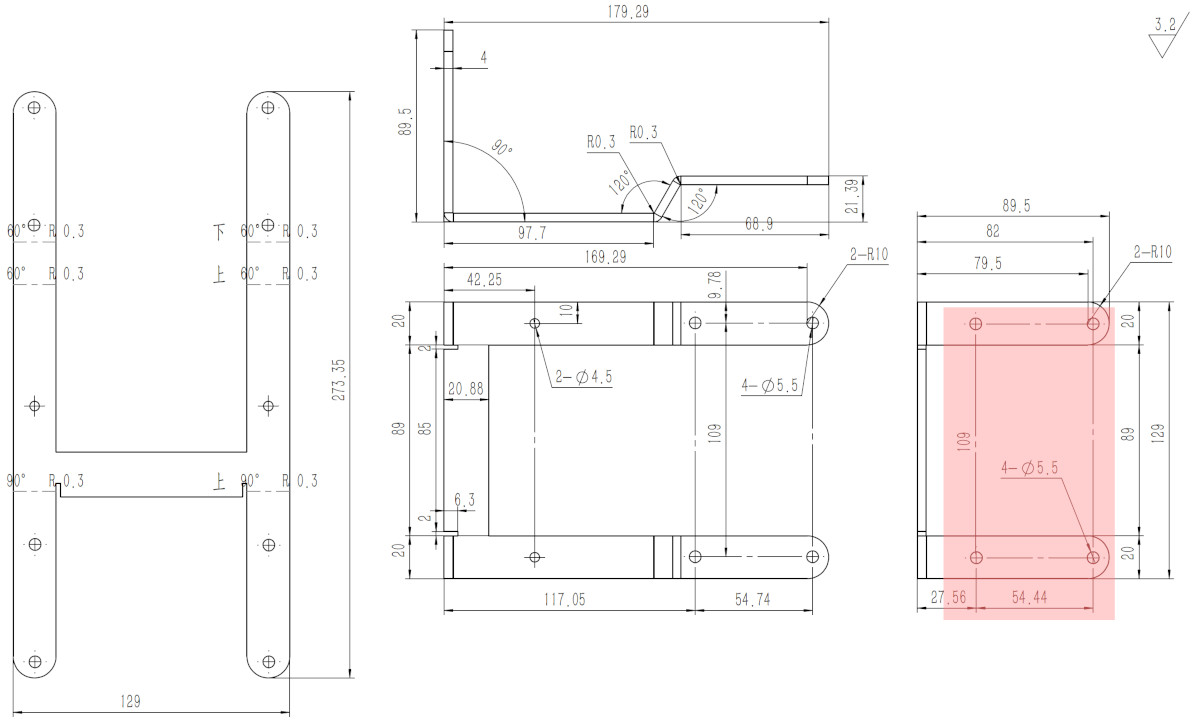

The bottom lid is made of 2mm anodised aluminium , that comes in 3 varieties to accommodate the different connectivity options: The Ethernet CITY will need a RJ-45 connector, while the LoRaWAN CITY will need a 7mm round opening for the SMA Antenna connector.

At the bottom, there is a lid with openings for the various connectors. This is made out of 2mm aluminium, anodised black:

Texts and logo are imprinted using laser engraving. Here is a quick video showing this manufacturing step:

The base is held in place by an A3 Stainless Steel custom support , used to mount the sensor to a wall or on a pole.

Here’s the result, including the stainless steel support, that turned out nicely:

Electrostatic coating

The stainless steel supports have been painted, not for protection that much but rather for a better look. We opted for a dark gray, keeping the colour range in the same zone, with a white ASA massive plastic enclosure and the strong black anodised aluminium lid. Here’s a video of the process:

New changes

The 4 long threaded rods that hold the plastic parts together are screwed to 4 rounded (mushroom) stainless steel nuts at the top, that are visible in the pictures. This initial design was very good and quick to assemble, however we came with an improvement already.

The top plastic part now is fully closed . The threaded rods are connecting to 4 internal nuts embedded in the plastic. This way we can avoid the 4 holes that in some cases can be problematic when it comes to rain, even if the screws are properly tightened, it is better to have full protection. The top is now full flat. Here is how this looks now:

Good thing we didn’t commit to a mould yet , as this change would have made it obsolete at a huge cost.

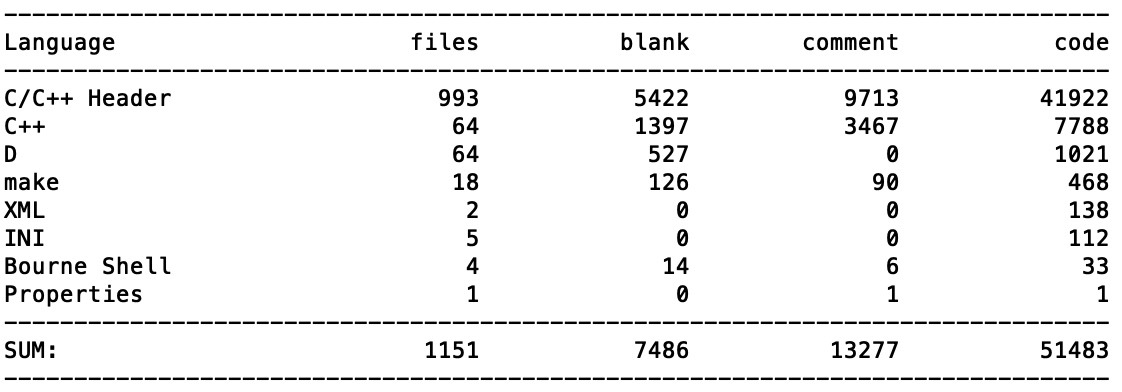

3. The new firmware

The software running on these devices underwent major updates too. We had to implement drivers for the new sensors, redundancy for the MEMs sensors and compensation for the new Stevenson Enclosure (that is very well ventilated). Specific care was given to the power saving mechanism that works with the battery management system. In a few words, the device checks the battery level and will go to sleep if the battery charge is insufficient to support operation and will resume once more power is available.

Ethernet drivers were added to support the new connectivity option. Of course, these features are defined by a custom config file specific to every device and memory economy is in place. The embedded webserver was also updated to present the new information, like GPS coordinates, battery level, internal voltage, together with the readings from the sensors.

4. Sensors and capabilities

The uRADMonitor CITY measures the following parameters:

| Sensor | Parameter | Minimum value | Maximum value |

| MEMS | Temperature | -40 °C | +85 °C |

| Humidity | 0% RH | 100% RH | |

| Barometric Pressure | 300 hPa | 1100 hPa | |

| Laser Scattering | PM1.0 | 0 μg/m³ | 1000 μg/m³ |

| PM2.5 | 0 μg/m³ | 1000 μg/m³ | |

| PM10 | 0 μg/m³ | 1000 μg/m³ | |

| Electrochemical 1ppb | Ozone | 0 ppm | 1ppm |

| Electrochemical 1ppb | Nitrogen Dioxide | 0 ppm | 1 ppm |

| Electrochemical 1ppb | Sulphur Dioxide | 0 ppm | 1 ppm |

| Electrochemical 1ppb | Carbon Monoxide | 0 ppm | 10 ppm |

Full datasheet is available on the product page.

5. Calibration of the electrochemical cells

The sensors used in uRADMonitor® CITY, especially those for determining gas concentration, offer measurements at a resolution of 1PPB, a value that is difficult to match with other products on the market. This performance is the result of an extremely careful electronic design, where the useful signal is differentiated from the noise level by innovative methods.

As these aspects are extremely sensitive, each gas cell is individually tested in the laboratory to ensure final performance of the uRADMonitor® CITY devices and an operator-endorsed laboratory test sheet is issued. Thus our sensors will be able to measure with very good accuracy the smallest variations of the tracked gases.

Performance tests and inter-device variations

The previous uRADMonitor CITY HW104 was just tested during AIRLAB 2023 against of tens of other competing products and there will be some time until we submit the new iteration to another lab for fresh tests. The report is available on their interactive platform or here.

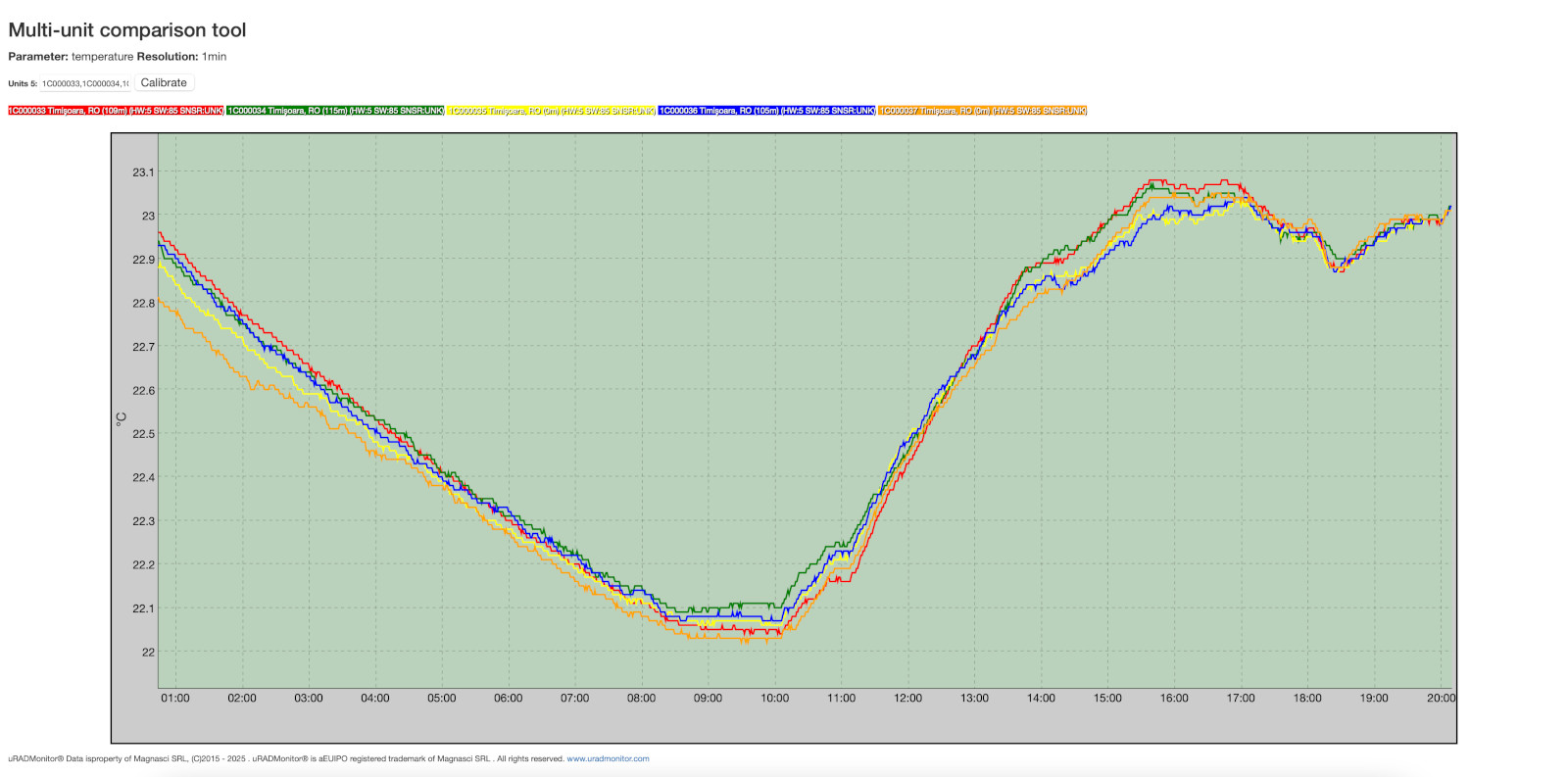

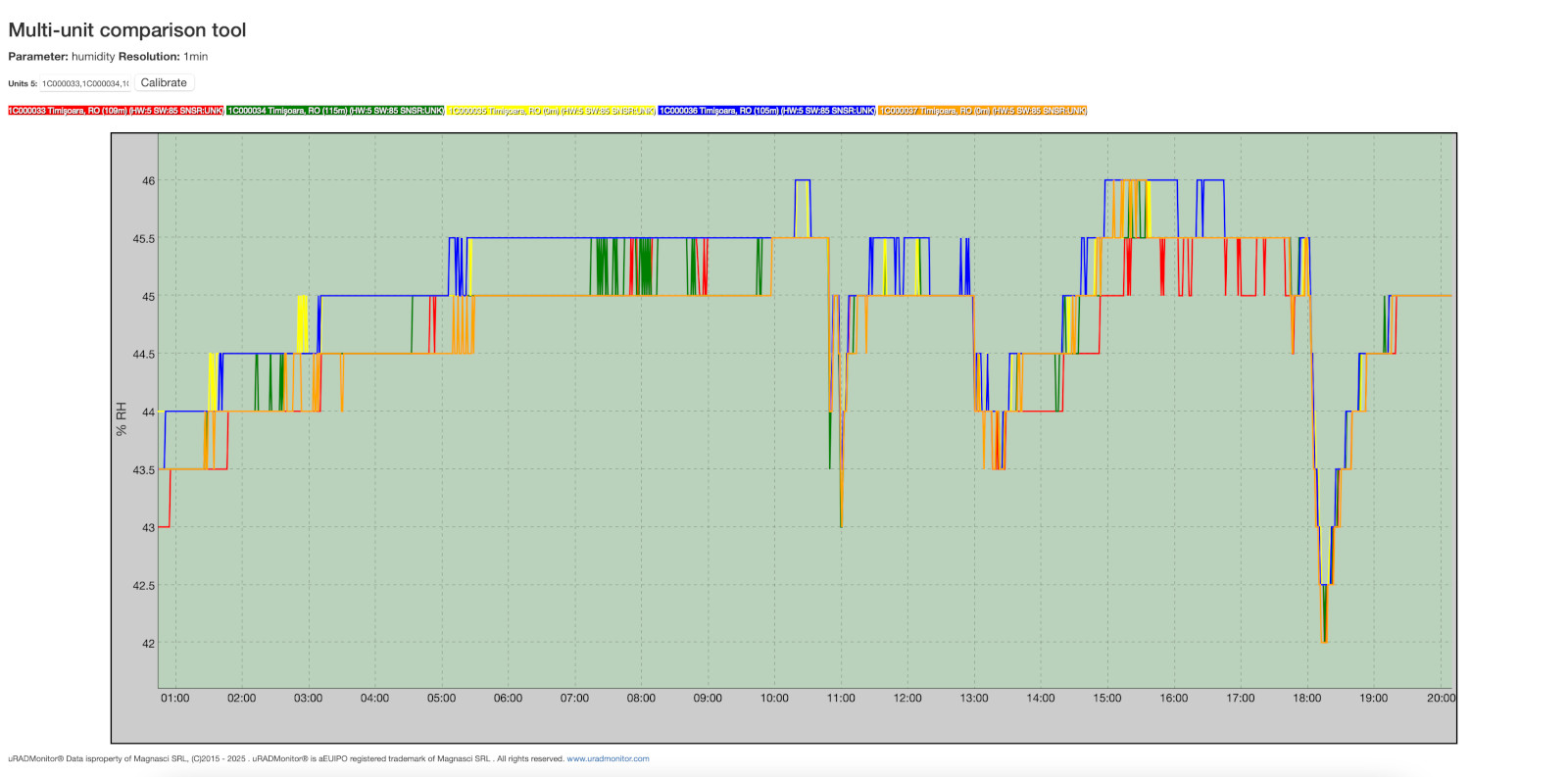

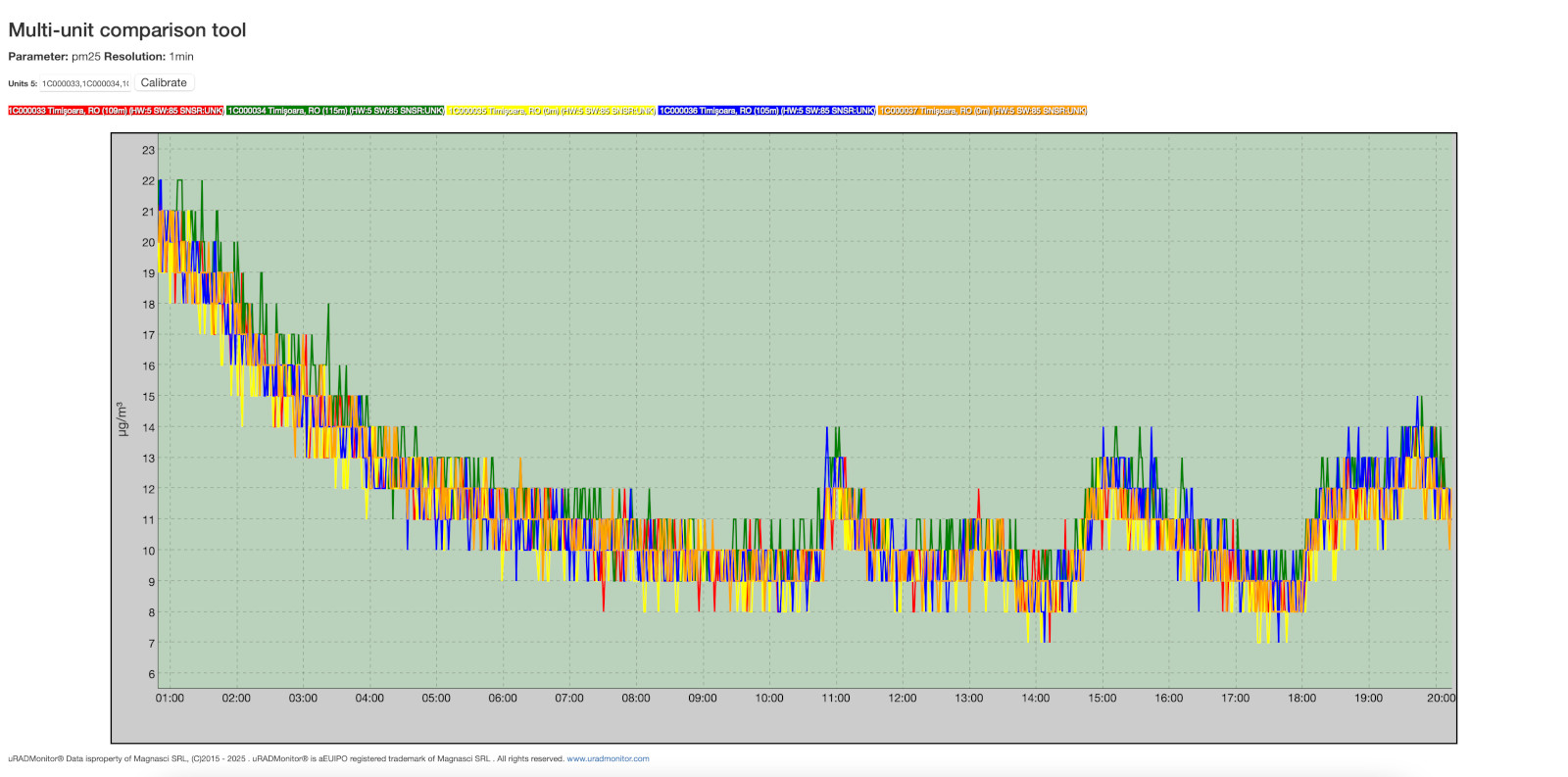

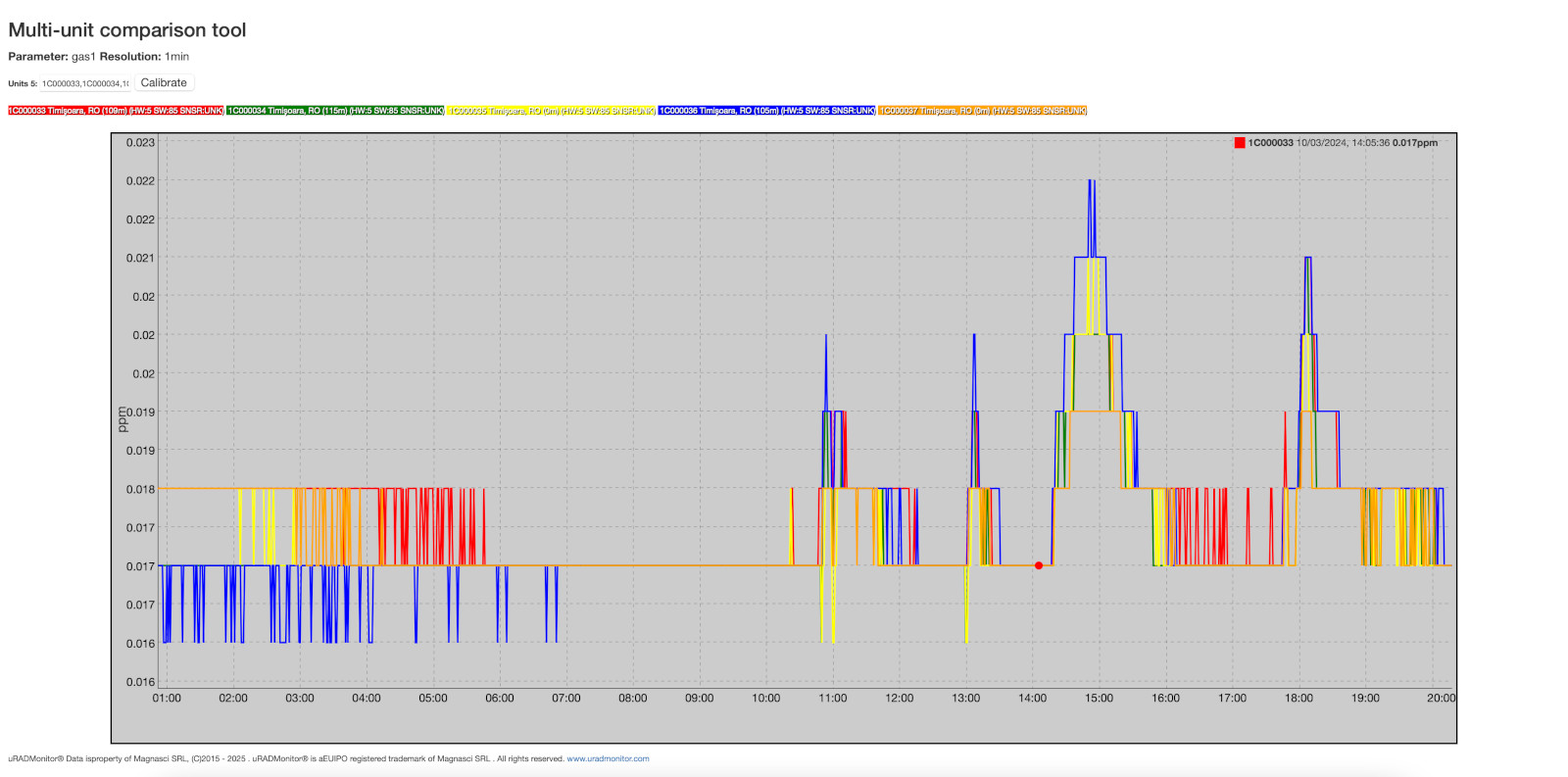

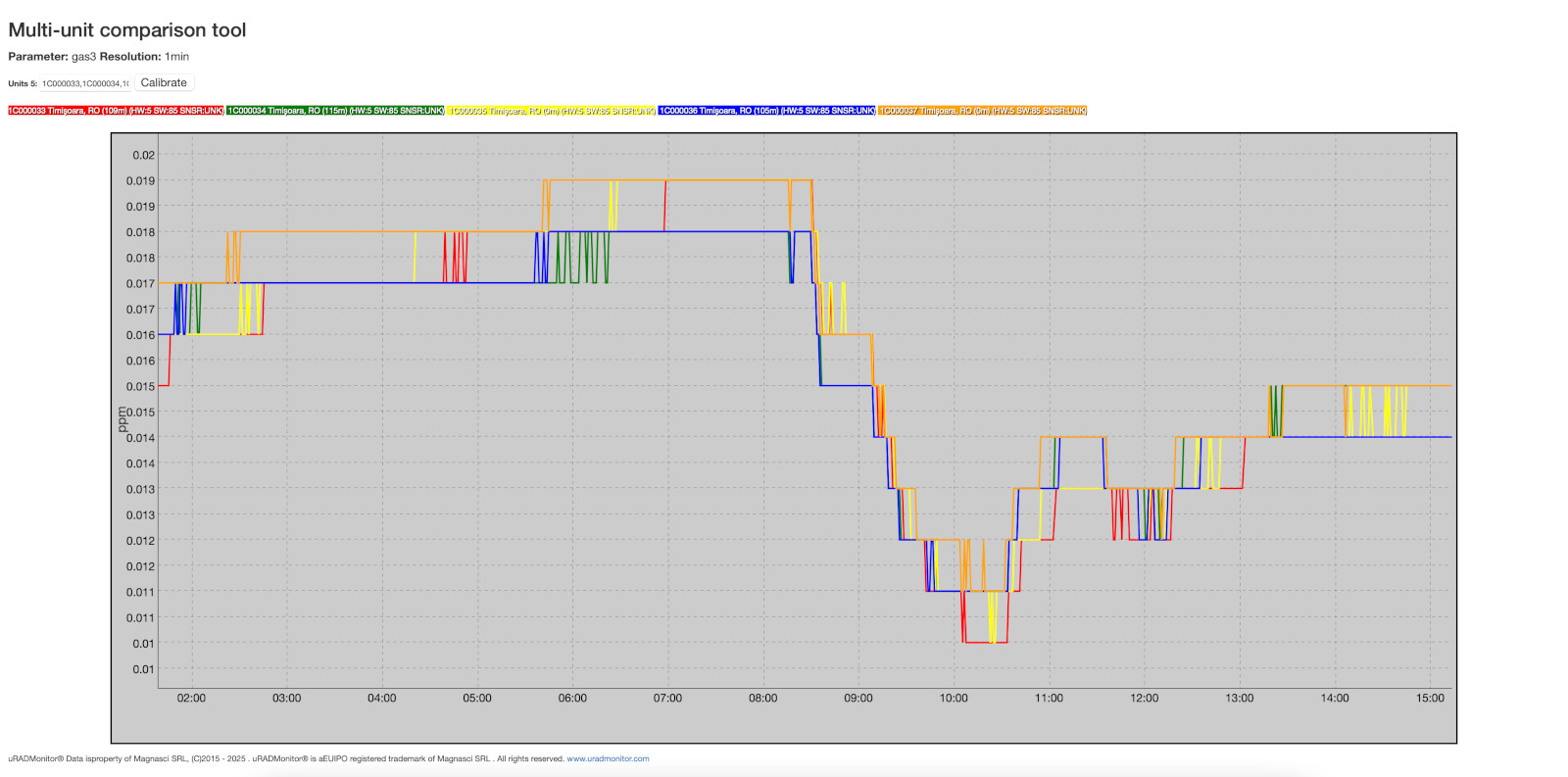

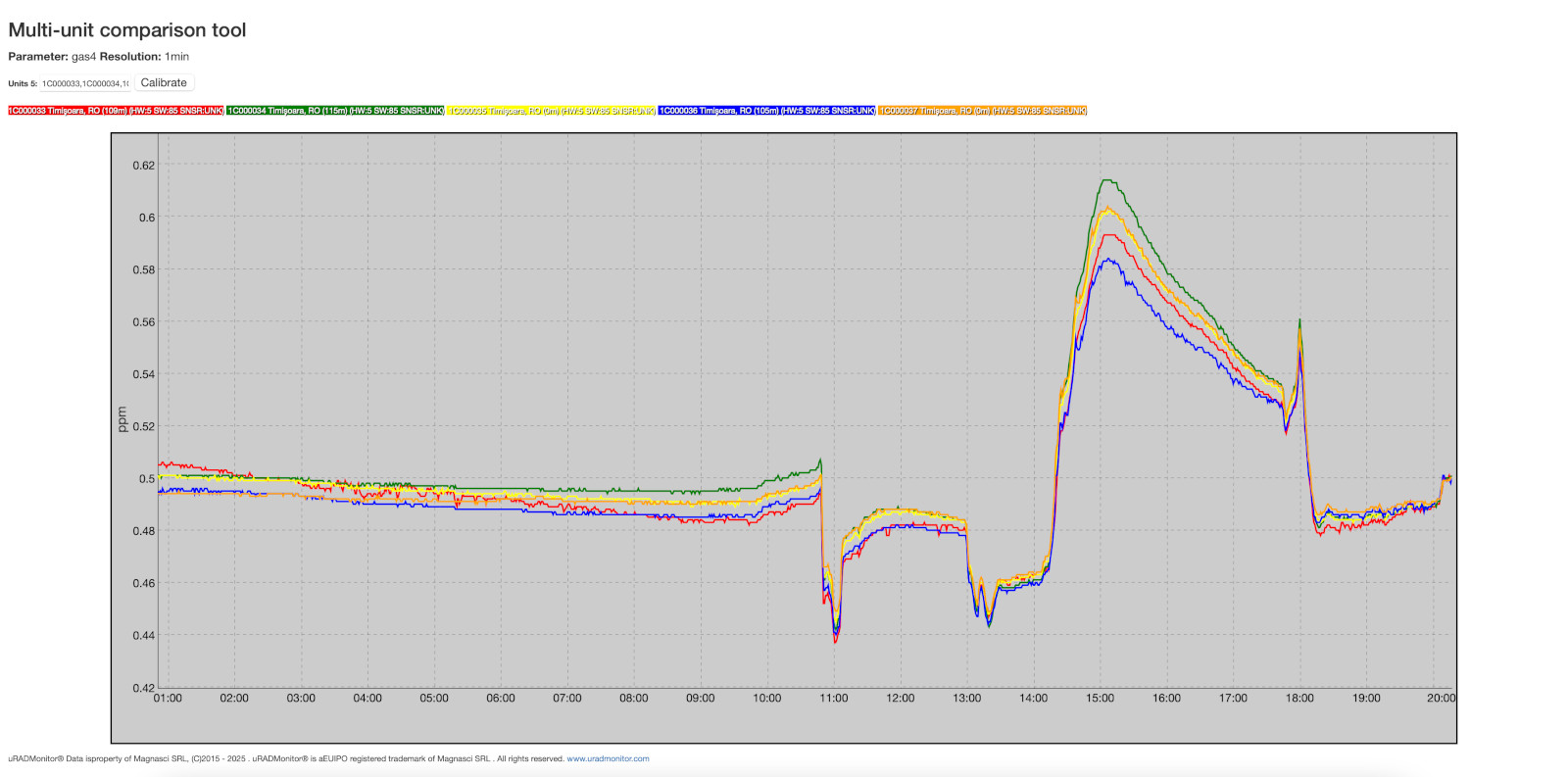

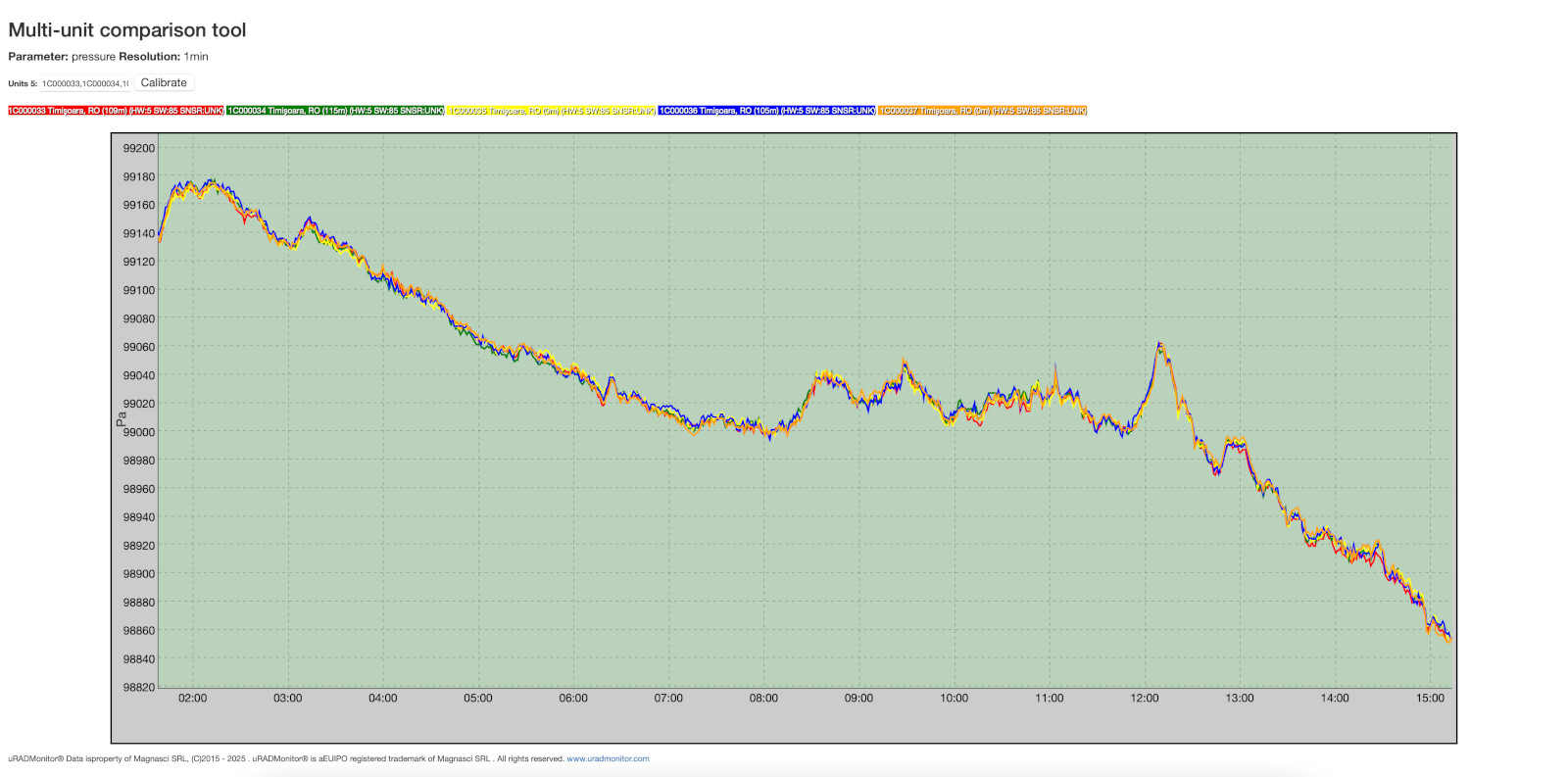

Now we ran a few local tests with the current hardware iteration, specifically to demonstrate the improved inter-device performance. 5 test CITY units were connected in parallel for this purpose:

Here are some of the results that show excellent correlation and very small inter-device variations:

Conclusion

From a technical point of view, it is easier to obtain good inter-device correlation at high gas concentrations, where the relative errors will hide in the bigger amplitude of the measurements. On the other hand, at very small gas concentrations, every tiny error becomes apparent. The gas concentrations in these tests were very small, in the order of a few PPBs , making the good correlation performance demonstrated here, an excellent result!

codemore code

~~~~